jaywhyy

Senior Member

- Joined

- Feb 19, 2013

- Messages

- 941

- Reaction score

- 339

The description was going by the Savile-Row, classical, for lack of a less pretentious word, definitions of bespoke tailoring and shoemaking.Did you read what you wrote? How would you know if someone was adjusting block patterns to customers? I know two bespoke tailors who do that because they like the outcomes. If MTM can have such drastic and precise adjustments, whats the difference to bespoke? What if the outcome is the same? How would you tell bespoke vs MTM?

Lets say someone is broadly a 40 R. If that guy went to a bespoke tailor, do you think his pattern is going to be unrecognizable to an off the rack pattern? Theres only so many ways to create a "house style", so the variables are further reduced because you are attempting to produce a specific outcome.

None of your definitions are accurate in my opinion, including the shoe example. Theres a bespoke maker on this forum who works off of standard lasts and adjusts them to the customer's feet. If you still dont see grey in the equation, you're ignoring it.

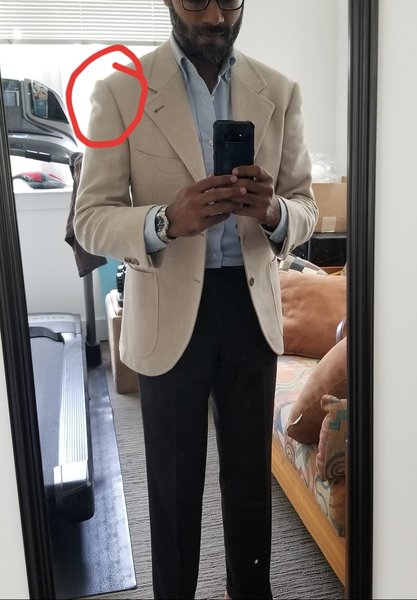

To me, the difference between MTM and bespoke is this: The two variables in question are fit and details, and in MTM there are limitations in the adjustments that can be made to those things, if at all because you are working with a pre-determined set of options. In bespoke, the limitations are the creativity and skill of the tailor and cutter.

I would concede there's a grey area in what constitutes a standard last or block pattern, but adjusting a finished last is much different from designing a personalized last from a standardized one...as is the adjustments made to the block pattern in an MTM operation versus bespoke.

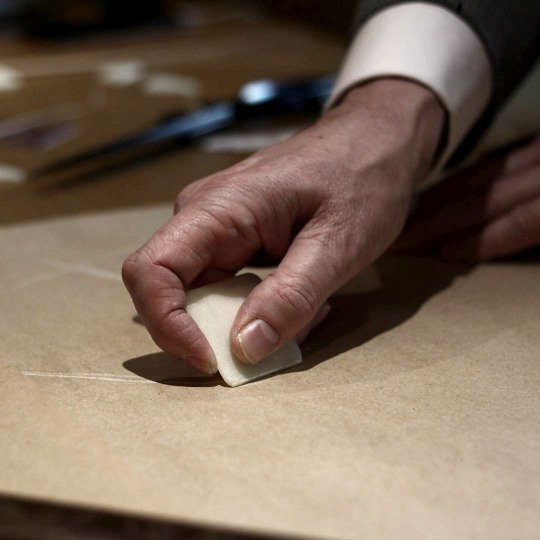

But I didn't adequately underscore that the differences described b/w MTM and bespoke were not univariate with respect to the block patterns. Per above, an MTM operation is going to have adjustments relayed to a factory, usually in the form of blinded measurements applied to the block pattern without much thought at the receiving end. With bespoke, adjustments are put into the cloth itself by the cutter, so details are not lost/warped in translation. And of course you have those older cutters relying on rock of eye, where, again, you could argue a block pattern is engrained in their brain.

In the end of bespoke, you should have your own personalized pattern/last. With a repeat MTM order, they input the same (or new) measurements into the block pattern. There is not a personalized pattern, but a set of personalized numbers.

Whether this yields a better fitting garment at the initial fitting is up for the debate, but there's a fundamental difference in the process.

If @Shirtmaven is still active, it would be great if he could chime in on the differences between an MTM versus bespoke option. This discussion, especially the use of block patterns in bespoke, has been debated before.

Edit: I would modify the analogy of MTM to be if someone measured your foot, relayed measurement changes over to the Alden factory, and someone on that end shaved/corked up a Barrie last based off those measurements. A (traditional) bespoke cordwainer will make the last with that big ole lasting knife, starting off with a very rudimentary standard last ala that famous Delos video.

Last edited: