jordong

Active Member

- Joined

- Mar 11, 2009

- Messages

- 29

- Reaction score

- 0

I have a new pair of Hellstern's the look recent. Are they still making new men's shoes? Was not able to find anything on the net.

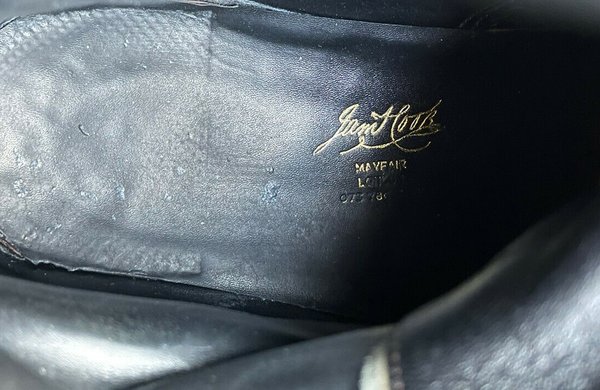

Hellstern was founded in the 1880s in Paris as a maker of ladies’ shoes. Subsequently they embarked into men’s shoes as well. They had a branch in London’s Bond Street for fifty odd years, from the Edwardian days to the early 60s.

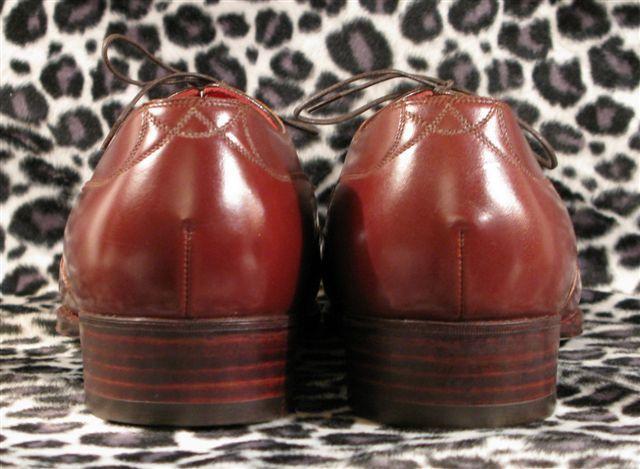

I do not know, if Hellstern had French and English production facilities, but those shoes featured look distinctly English due to the way the Norwegian construction is done (two rows of stitching), as well as the back lining made from upper leather.

I might have been the owner of those shoes. They were up on eBay maybe six months ago. I observed them, but then I decided not to bid. They were too small and I do not collect shoes, just to look at them. (Back then, they did not get any bids at all).

Here are the seller’s photographs, which I saved. (I like the medallion, I might copy it at some point.)

I believe it is the identical pair of shoes.

I have a new pair of Hellstern's the look recent. Are they still making new men's shoes? Was not able to find anything on the net.