- Joined

- Aug 30, 2019

- Messages

- 4,268

- Reaction score

- 32,324

Last week I received my pair of shoes from the Archibald of London sale they offered via google docs on their threads here on SF over the past week or so – The pair I got was the Anticato Volonata color. I purchased these at the sale price that was available to SF via the Google Doc with the sole intention of reviewing them. I was up front with Archibald and disclosed that I was planning to review them and compare them to other hand welted options that are out there (or welted without gemming.) I took some time this that evening to write a review of the Archibald of London shoes I received, after writing it up, I am posting a different review – One that I must say I am shocked to be posting. I've tried to be as fair as I could in both my original thoughts and my updated review.

The selling point of these shoes aside from competing with shoes much more expensive than they are was that they construction was hand welted. When considering dress shoes you have a number of options for construction - Glued, blake, blake rapid, bologna, goodyear, goodyear welted without gemming and hand welted with hand welted shoes being the most intensive to make and typically the most expensive.

One need only look to Archibald's promotional materials to start to get a sense of what hand welting is "The pinnacle of shoemaking, the practice of hand-welting is lengthy, precise and robust. It has never been easy and thus is now rare. There are few artisans still able to do it and few luxury brands offer it."

After an initial review of the shoes I had some questions based on the feel of the shoes, particularly the insole and the lack of the typical “hand welted bump” that you see on these shoes, and had been contemplating opening them up to see if I could find out about the internal components but this pushed me to the point where I decided that I was going to cut them open and get to the bottom of some things that were nagging at me. I am not a shoemaker and I am not an expert but I know enough to be able to state that the most important finding was that these shoes ARE NOT hand welted. They aren’t goodyear welted. They aren’t goodyear a mano, they aren’t goodyear welted without gemming.

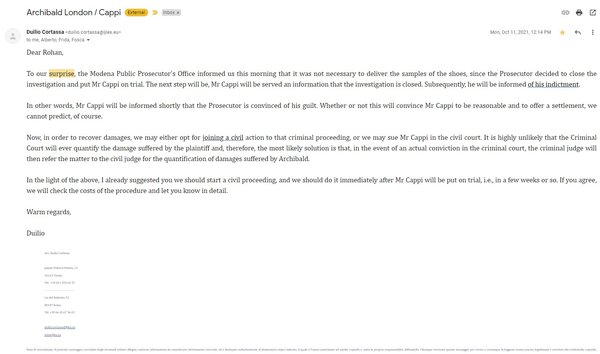

After this realization I reached out to the guys at Archibald for comment as their product was not as described for this post that I intended to post last Friday to get their comments. Instead of posting, I ended up spending some time speaking with the Archibald team and walking them through my (non-expert) findings. My understanding is that the guys at Archibald have now alerted their customers and are working on a solution and an answer because frankly I think the StyleForum community deserves an answer.

While they worked on getting that answer, I requested that they remove the shoes from their storefront which some of you noticed they did last week within hours of our discussion. At this point, I’m not going to defend what happened or try and explain it as frankly I'm not on their team to know what happened and I'm not a shoemaker or an expert so I don't want to make many claims other than what I see as a person who enjoys shoes but I have deconstructed the shoe and have photos of what I see. Perhaps someone who is better informed than I can comment as to the construction method that is actually used.

For transparency, I have the remainder of the review below in a spoiler as well for what my initial thoughts were but many of those points are now moot as they relied upon the belief that the shoes were in fact hand-welted but I feel that it’s appropriate to share my initial thoughts before opening the shoes up and another spoiler that has photos of the deconstructed shoes and an effort at a rendering of the construction method employed.

The selling point of these shoes aside from competing with shoes much more expensive than they are was that they construction was hand welted. When considering dress shoes you have a number of options for construction - Glued, blake, blake rapid, bologna, goodyear, goodyear welted without gemming and hand welted with hand welted shoes being the most intensive to make and typically the most expensive.

One need only look to Archibald's promotional materials to start to get a sense of what hand welting is "The pinnacle of shoemaking, the practice of hand-welting is lengthy, precise and robust. It has never been easy and thus is now rare. There are few artisans still able to do it and few luxury brands offer it."

After an initial review of the shoes I had some questions based on the feel of the shoes, particularly the insole and the lack of the typical “hand welted bump” that you see on these shoes, and had been contemplating opening them up to see if I could find out about the internal components but this pushed me to the point where I decided that I was going to cut them open and get to the bottom of some things that were nagging at me. I am not a shoemaker and I am not an expert but I know enough to be able to state that the most important finding was that these shoes ARE NOT hand welted. They aren’t goodyear welted. They aren’t goodyear a mano, they aren’t goodyear welted without gemming.

After this realization I reached out to the guys at Archibald for comment as their product was not as described for this post that I intended to post last Friday to get their comments. Instead of posting, I ended up spending some time speaking with the Archibald team and walking them through my (non-expert) findings. My understanding is that the guys at Archibald have now alerted their customers and are working on a solution and an answer because frankly I think the StyleForum community deserves an answer.

While they worked on getting that answer, I requested that they remove the shoes from their storefront which some of you noticed they did last week within hours of our discussion. At this point, I’m not going to defend what happened or try and explain it as frankly I'm not on their team to know what happened and I'm not a shoemaker or an expert so I don't want to make many claims other than what I see as a person who enjoys shoes but I have deconstructed the shoe and have photos of what I see. Perhaps someone who is better informed than I can comment as to the construction method that is actually used.

For transparency, I have the remainder of the review below in a spoiler as well for what my initial thoughts were but many of those points are now moot as they relied upon the belief that the shoes were in fact hand-welted but I feel that it’s appropriate to share my initial thoughts before opening the shoes up and another spoiler that has photos of the deconstructed shoes and an effort at a rendering of the construction method employed.

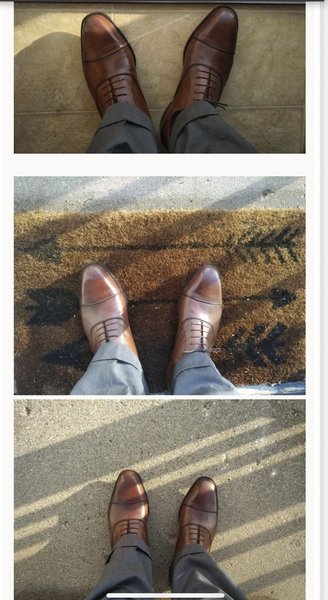

Original photos I took:

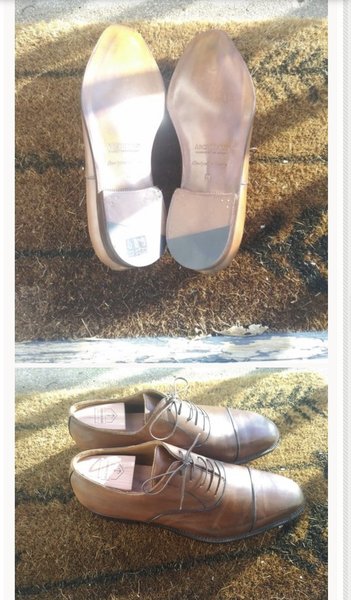

Welt joint and heel lift

Stitching of the sole

Lack of hand welted bumps

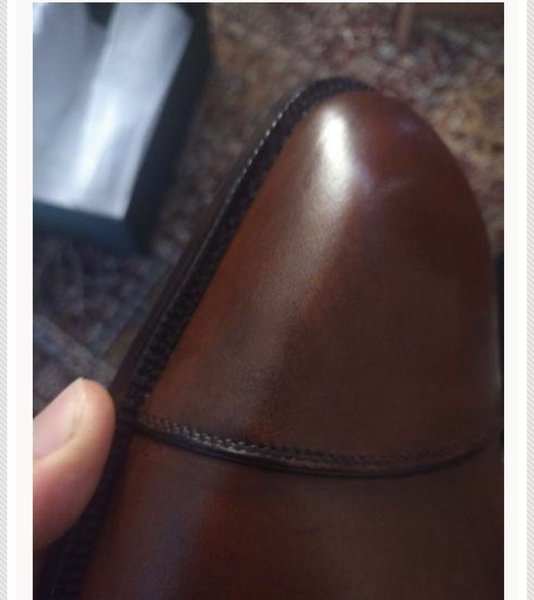

After cutting the stitches, a decorative welt was able to be removed exposing the upper leather being hinged and stitched through connecting a decorative welt, the upper and the sole

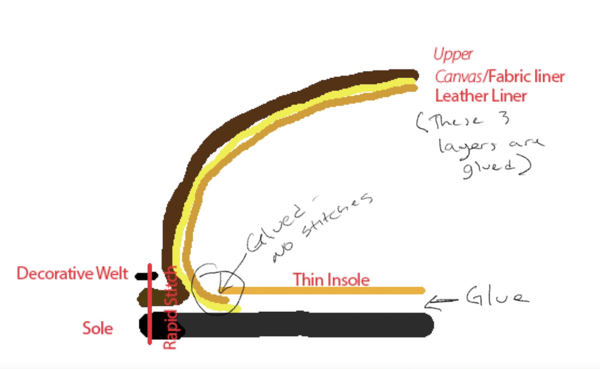

Upon removing the sole you can see the internal components of the shoe - There was cork in the footbed which you can see some of the remnants of. You can see the upper, a canvas internal layer and the liner glued together with the canvas and liner being glued to the insole and the shank.

As we peel those layers back we can see the upper, canvas liner and liner were glued to the insole and no stitching is there connecting the three layers or any of the layers to the insole.

You're able to lift the upper from the subsequent layers and see that they were glued together except for the bar stitch.

And finally, we can break the glue from the liner and the canvas liner in the middle layer.

Essentially leaving you with a construction method that resembles this

Welt joint and heel lift

Stitching of the sole

Lack of hand welted bumps

After cutting the stitches, a decorative welt was able to be removed exposing the upper leather being hinged and stitched through connecting a decorative welt, the upper and the sole

Upon removing the sole you can see the internal components of the shoe - There was cork in the footbed which you can see some of the remnants of. You can see the upper, a canvas internal layer and the liner glued together with the canvas and liner being glued to the insole and the shank.

As we peel those layers back we can see the upper, canvas liner and liner were glued to the insole and no stitching is there connecting the three layers or any of the layers to the insole.

You're able to lift the upper from the subsequent layers and see that they were glued together except for the bar stitch.

And finally, we can break the glue from the liner and the canvas liner in the middle layer.

Essentially leaving you with a construction method that resembles this

So I received my pair from the sale – The pair I got was the Anticato Volonata color. I purchased these at the sale price that was available to SF via the Google Doc with the sole intention of reviewing them. I was up front with Archibald and disclosed that I was planning to review them and compare them to other hand welted options that are out there (or welted without gemming.)

In full disclosure – I am aware that the finishing of the leather on these was a mistake at the factory due to their maker and am told this occurred due to travel restrictions from Covid so I will NOT be commenting on the leather color or the pebbling – These are the only defects that I was made aware of and I knowingly ordered them anyways, so I don’t feel it’s my place to critique this any further.

First for the buying experience – The Archibald guys were very pleasant to deal with and shipped quickly. It made it from the UK to the US in 2 or 3 days.

The packaging was neatly done. The box is on the lighter side but survived shipping which is always a good sign and I don’t keep the boxes anyways. Included was a spare set of laces (the laces in the shoe and the spare set were both waxed round laces), two shoe bags on top of the shoes and then a shoehorn made of horn. These are nice details and I appreciate getting them but aren't game changers as I place the priority on the shoes.

Before I get to the actual shoes themselves I think a discussion is in order of what these are being sold as. Archibald shoes are sold as a premium product that is supposed to compete with the highest quality of men’s dress shoes at a better price point because of their direct to consumer model. From that description, one would expect top grade leathers, premium components, quality making, finishing and design – On top of this, they’re hand lasted and hand welted with a machine stitched outsole. I think this is important because this is the lens that I am going to write this review from. Their goal is to deliver really excellent shoes that compete with shoes at 3x the price. Having experience with shoes at that price point, that’s what I’m going to compare to.

The recommended price on these is £470 or approximately $550 ex vat which puts them just over Vass pricing. Just slightly less than Enzo Bonafe and Yeossal. Their current “naked” pricing drops them to about $325 these are competitive with Meermin’s Linea Maestro line and with some of the recent Vass sales during the pandemic. I think it’s important going into this to know what is being sold so we can look at whether that is being delivered.

The last is ok looking to my eye. It isn’t particularly refined but has a relatively modern look. I wouldn’t call it sleek but I wouldn’t call it particularly bulbous. Their photography on their website lets them down here and they look better in person than they do on the website as far as the last shape goes. I would describe the last as a lower instep but high volume last. It also has a lot of toe spring (over 1”) which is not my preference in a dress shoe. I also believe reducing the vertical volume in the toe box would benefit them in order to avoid really excessive creasing and an odd flex point. There are a couple places where the leather has collapsed a bit in the quarters.

Leather – I won’t comment on the finishing of the leather as I mentioned earlier but the leather could use an upgrade. Switching to d’Annonay, Haas, or Weinheimer would be my recommendation. The leather on my pair is slightly irregular and has several areas of loose grain – The leather feels ok but based on prior reviews I expected better – It isn’t on the level of the brands it was compared to. The way the leather flexes concerns me for long term wear. I’m told that they are in talks with some other tanneries about getting skins from there in the future and would recommend they continue those discussions and this would be an upgrade that would alleviate these concerns. Bringing someone on board who really knows leather would be an asset to them.

Finishing (making, not leather) – I think this is where Archibald really lets themselves down the most and in large part I think it’s because I’ve followed their thread for a while and have seen the discussions of comparison to other shoes so I was wondering if I would see that show up in the finishing details.

Soles - These have about 5 SPI on the sole stitching and I will say that the stitching on the sole is very neat. There is no fudging or anything crazy but the stitch density is roughly the same throughout the entire shoe and is the same distance from the edge around. The welt joint isn’t perfect but it isn’t as bad as some of the others that have been posted and I’m ok with it at this price point.

Uppers – The stitching on the upper is relatively consistent – In a couple places it gets a little close to the edge and floats a bit but at a shoe in this price point I think that is acceptable.

My bigger concern is the quarters, the closing and the edge work. The edges of the quarters is frayed and pretty raw - It doesn’t look particularly good. The closing at the back, the heel closure has a tab similar to many makers but is not flush with the shoe and the skiving is non-existent. I’d recommend skiving this to get it to sit more flush and making sure the stitching holds the entire thing down.

The heel finishing is ok but it isn’t particularly tightly cut. It’s not quite 360 degree welt territory but it’s close. The heel layers aren’t cut evenly but by the time you get to the bottom it sits flush so that will work. Unfortunately the combination heel their maker put together has a gap and they aren’t cut evenly.

Overall, there isn’t really anything egregious in the finishing as far as the making goes for this price point but I think it’s worth covering because of what they want to be and what they claim to be. There are things that can be improved and I would expect none of these issues I pointed out to be present in a shoe at $1,000 or more (and none of my shoes at that price have these issues) and frankly, wouldn’t expect them at the $600+ range either and I’d expect better components. But for somewhere in the neighborhood of $350-500 I’m ok with them and if they provide another lower cost option to get into hand-welted footwear I think we can all celebrate that.

In full disclosure – I am aware that the finishing of the leather on these was a mistake at the factory due to their maker and am told this occurred due to travel restrictions from Covid so I will NOT be commenting on the leather color or the pebbling – These are the only defects that I was made aware of and I knowingly ordered them anyways, so I don’t feel it’s my place to critique this any further.

First for the buying experience – The Archibald guys were very pleasant to deal with and shipped quickly. It made it from the UK to the US in 2 or 3 days.

The packaging was neatly done. The box is on the lighter side but survived shipping which is always a good sign and I don’t keep the boxes anyways. Included was a spare set of laces (the laces in the shoe and the spare set were both waxed round laces), two shoe bags on top of the shoes and then a shoehorn made of horn. These are nice details and I appreciate getting them but aren't game changers as I place the priority on the shoes.

Before I get to the actual shoes themselves I think a discussion is in order of what these are being sold as. Archibald shoes are sold as a premium product that is supposed to compete with the highest quality of men’s dress shoes at a better price point because of their direct to consumer model. From that description, one would expect top grade leathers, premium components, quality making, finishing and design – On top of this, they’re hand lasted and hand welted with a machine stitched outsole. I think this is important because this is the lens that I am going to write this review from. Their goal is to deliver really excellent shoes that compete with shoes at 3x the price. Having experience with shoes at that price point, that’s what I’m going to compare to.

The recommended price on these is £470 or approximately $550 ex vat which puts them just over Vass pricing. Just slightly less than Enzo Bonafe and Yeossal. Their current “naked” pricing drops them to about $325 these are competitive with Meermin’s Linea Maestro line and with some of the recent Vass sales during the pandemic. I think it’s important going into this to know what is being sold so we can look at whether that is being delivered.

The last is ok looking to my eye. It isn’t particularly refined but has a relatively modern look. I wouldn’t call it sleek but I wouldn’t call it particularly bulbous. Their photography on their website lets them down here and they look better in person than they do on the website as far as the last shape goes. I would describe the last as a lower instep but high volume last. It also has a lot of toe spring (over 1”) which is not my preference in a dress shoe. I also believe reducing the vertical volume in the toe box would benefit them in order to avoid really excessive creasing and an odd flex point. There are a couple places where the leather has collapsed a bit in the quarters.

Leather – I won’t comment on the finishing of the leather as I mentioned earlier but the leather could use an upgrade. Switching to d’Annonay, Haas, or Weinheimer would be my recommendation. The leather on my pair is slightly irregular and has several areas of loose grain – The leather feels ok but based on prior reviews I expected better – It isn’t on the level of the brands it was compared to. The way the leather flexes concerns me for long term wear. I’m told that they are in talks with some other tanneries about getting skins from there in the future and would recommend they continue those discussions and this would be an upgrade that would alleviate these concerns. Bringing someone on board who really knows leather would be an asset to them.

Finishing (making, not leather) – I think this is where Archibald really lets themselves down the most and in large part I think it’s because I’ve followed their thread for a while and have seen the discussions of comparison to other shoes so I was wondering if I would see that show up in the finishing details.

Soles - These have about 5 SPI on the sole stitching and I will say that the stitching on the sole is very neat. There is no fudging or anything crazy but the stitch density is roughly the same throughout the entire shoe and is the same distance from the edge around. The welt joint isn’t perfect but it isn’t as bad as some of the others that have been posted and I’m ok with it at this price point.

Uppers – The stitching on the upper is relatively consistent – In a couple places it gets a little close to the edge and floats a bit but at a shoe in this price point I think that is acceptable.

My bigger concern is the quarters, the closing and the edge work. The edges of the quarters is frayed and pretty raw - It doesn’t look particularly good. The closing at the back, the heel closure has a tab similar to many makers but is not flush with the shoe and the skiving is non-existent. I’d recommend skiving this to get it to sit more flush and making sure the stitching holds the entire thing down.

The heel finishing is ok but it isn’t particularly tightly cut. It’s not quite 360 degree welt territory but it’s close. The heel layers aren’t cut evenly but by the time you get to the bottom it sits flush so that will work. Unfortunately the combination heel their maker put together has a gap and they aren’t cut evenly.

Overall, there isn’t really anything egregious in the finishing as far as the making goes for this price point but I think it’s worth covering because of what they want to be and what they claim to be. There are things that can be improved and I would expect none of these issues I pointed out to be present in a shoe at $1,000 or more (and none of my shoes at that price have these issues) and frankly, wouldn’t expect them at the $600+ range either and I’d expect better components. But for somewhere in the neighborhood of $350-500 I’m ok with them and if they provide another lower cost option to get into hand-welted footwear I think we can all celebrate that.