dfoverdx

Senior Member

- Joined

- Jun 1, 2012

- Messages

- 261

- Reaction score

- 67

executive summary; sicily best tailor, napels sucks, london lounge best fabric

No i am not generalizing, just making constructive critiques.

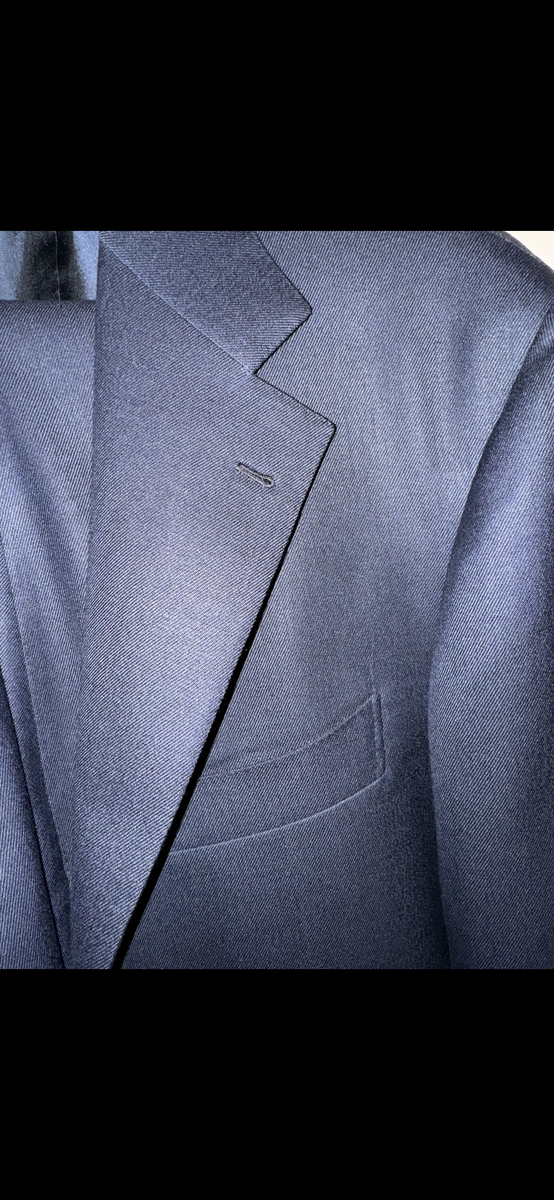

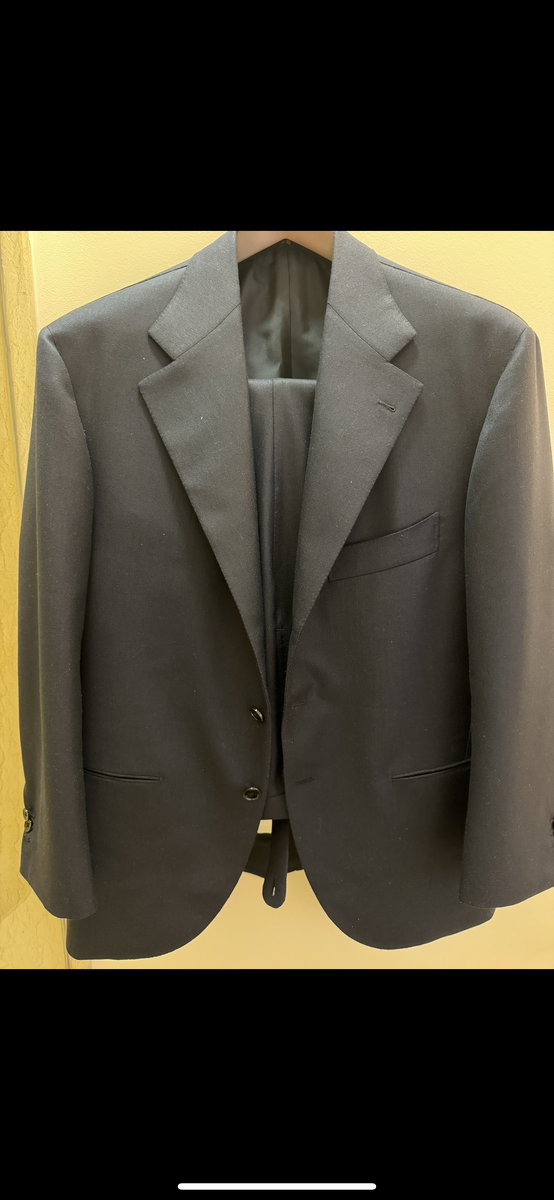

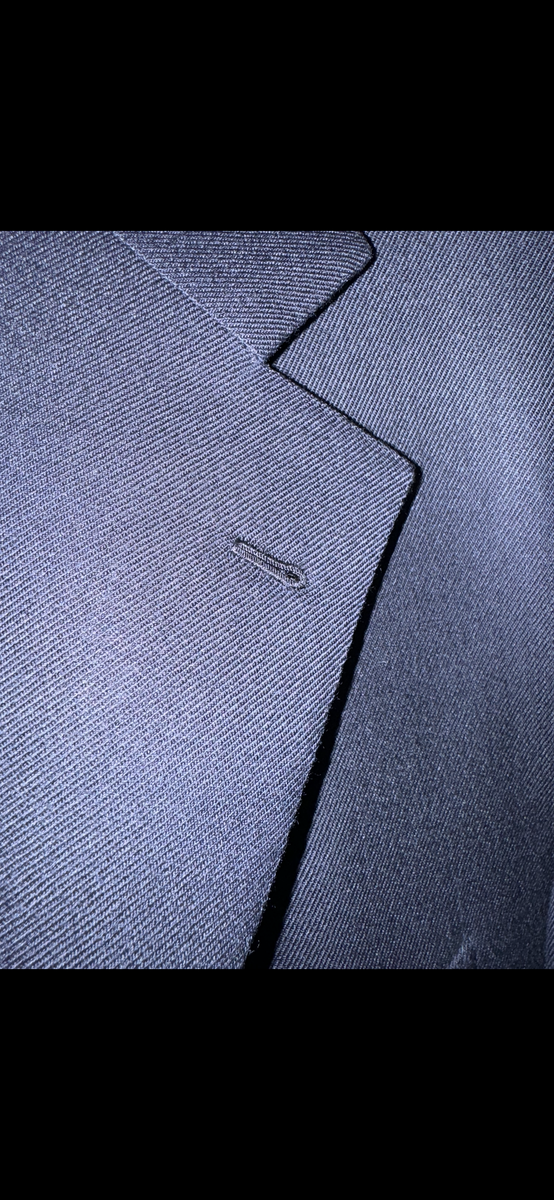

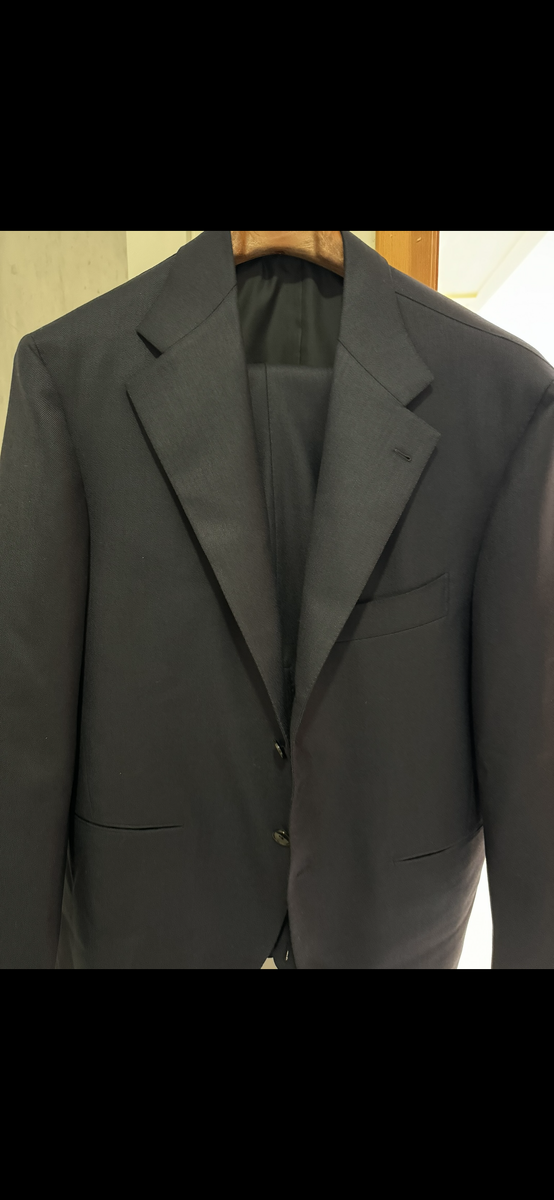

The second SB looks good, better than the first one. I am not saying it sucks, simply comparing both.

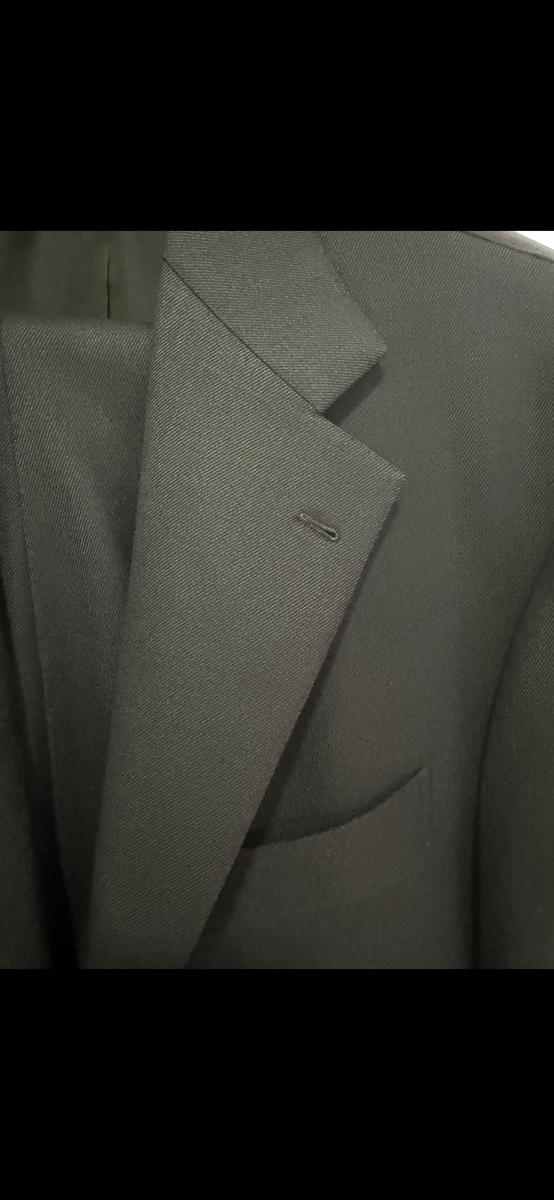

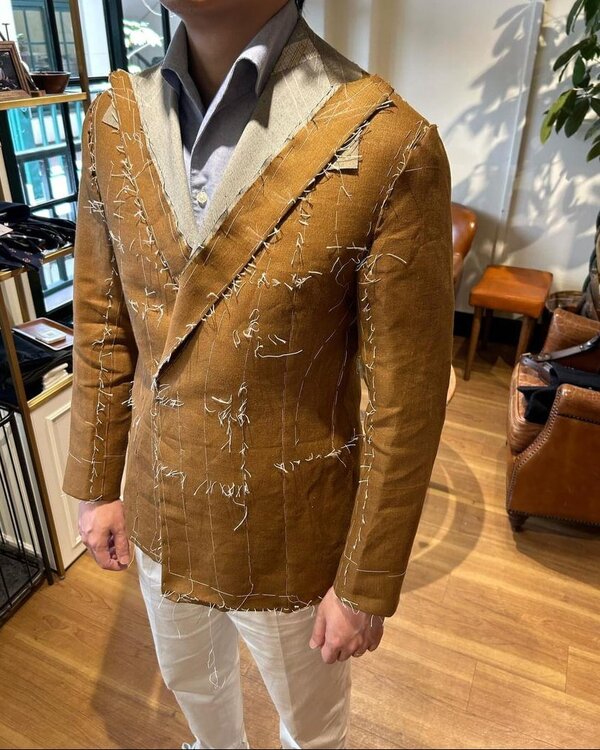

Now the back of the DB, it looks good from the front but back is not good. it's again this messy back, i am not saying that back should be perfect but yet there's still too much mess on the back. And i am saying again, the solution here is not about "cleaning" the back because he will end up with a tight suit.