- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

Glen,

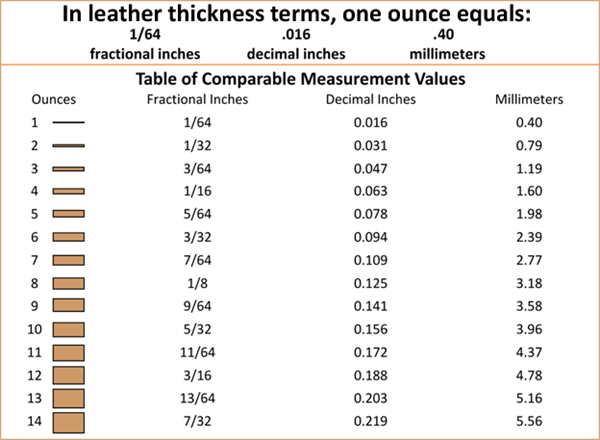

In English influenced parts of the Trade, outsoles and insoles are typically measured in "irons"...with one iron being equal to 1/48". So 12 iron is 1/4" or 16 ounce. How that convention originated, I don't know but many of the old weights and measures were based on common and easily referenced body parts or materials--such as "three barleycorns=one inch.

It varies from maker to maker, and according to style, of course, but in this country, a 10-11 iron insole is "typical" for a a man's shoe. In other parts of the world all leather--uppers and soling--may be measured in millimeters. It's certainly been that way in all my dealings with German companies.

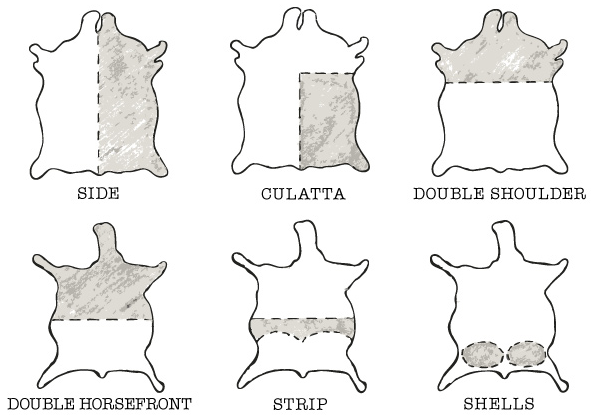

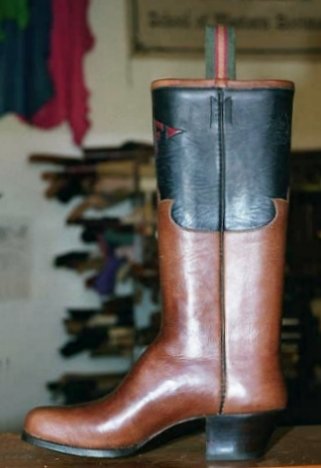

Insole thicknesses probably vary more widely but I would say 8 iron is probably considered neither too heavy nor too light. I myself might be more in the neighborhood of 9-10 iron depending on whether I am making a man's shoe or a boot. I might go as thin as 6 iron for a woman's shoe. I do know makers who use 6 iron insole shoulder (from Baker, mind you) for men's shoes, as well.

Of course, it goes without saying that much of this depends upon construction techniques. A goodyear welted shoe need not have a very thick insole at all. May not even be leather.

Upper leather is usually measured in ounces...a nice man's dress shoe probably tops out at 4 ounce. I use some leathers such as kangaroo that can be as lightweight as 2-3 ounces. 6 ounce is really too heavy for a dress shoe, in my opinion. And when you factor in a lining that will usually be at least 3 ounce and sometimes 4...for all quality shoes...an 8 ounce upper, even for work boots, is going to be plenty heavy and stiff.

--

I would like to ask a question about leather thickness in regard to shoe leather:

I know you can buy leather in different thicknesses, but I am curious as to the range of thickness for different parts of the shoe.

What is the typical range of thickness for a leather outsole (12 to 16 oz)?

What is the typical range of thickness for a leather insole (2 to 3 oz)?

What is the typical range of thickness of leather for the upper of a business/dress shoe (4 to 6 oz)? For a work boot (6 to 8 oz)?

I have also heard the term Iron used when specifying leather thickness, where does that come from?

Glen,

In English influenced parts of the Trade, outsoles and insoles are typically measured in "irons"...with one iron being equal to 1/48". So 12 iron is 1/4" or 16 ounce. How that convention originated, I don't know but many of the old weights and measures were based on common and easily referenced body parts or materials--such as "three barleycorns=one inch.

It varies from maker to maker, and according to style, of course, but in this country, a 10-11 iron insole is "typical" for a a man's shoe. In other parts of the world all leather--uppers and soling--may be measured in millimeters. It's certainly been that way in all my dealings with German companies.

Insole thicknesses probably vary more widely but I would say 8 iron is probably considered neither too heavy nor too light. I myself might be more in the neighborhood of 9-10 iron depending on whether I am making a man's shoe or a boot. I might go as thin as 6 iron for a woman's shoe. I do know makers who use 6 iron insole shoulder (from Baker, mind you) for men's shoes, as well.

Of course, it goes without saying that much of this depends upon construction techniques. A goodyear welted shoe need not have a very thick insole at all. May not even be leather.

Upper leather is usually measured in ounces...a nice man's dress shoe probably tops out at 4 ounce. I use some leathers such as kangaroo that can be as lightweight as 2-3 ounces. 6 ounce is really too heavy for a dress shoe, in my opinion. And when you factor in a lining that will usually be at least 3 ounce and sometimes 4...for all quality shoes...an 8 ounce upper, even for work boots, is going to be plenty heavy and stiff.

--

Last edited: