Zapasman

Distinguished Member

- Joined

- Oct 2, 2014

- Messages

- 3,726

- Reaction score

- 2,936

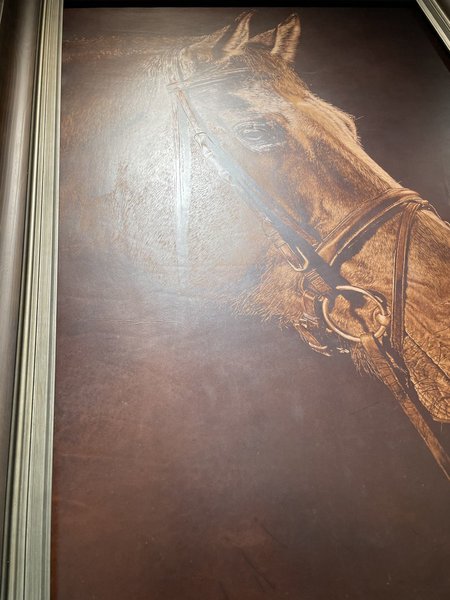

It was not my intention to talk about brands/countries of manufacturing here. In a way, I was forced to give a clue of the manufacturer in order to stop answering some private messages of other members asking me about the brand. On the other hand, I would like to see much more transparency in companies. That is what it really matters me as a customer.