asturiano

Senior Member

- Joined

- Jun 2, 2011

- Messages

- 178

- Reaction score

- 28

so just quoting the bolded part.. 2 pictures with 2 different questions

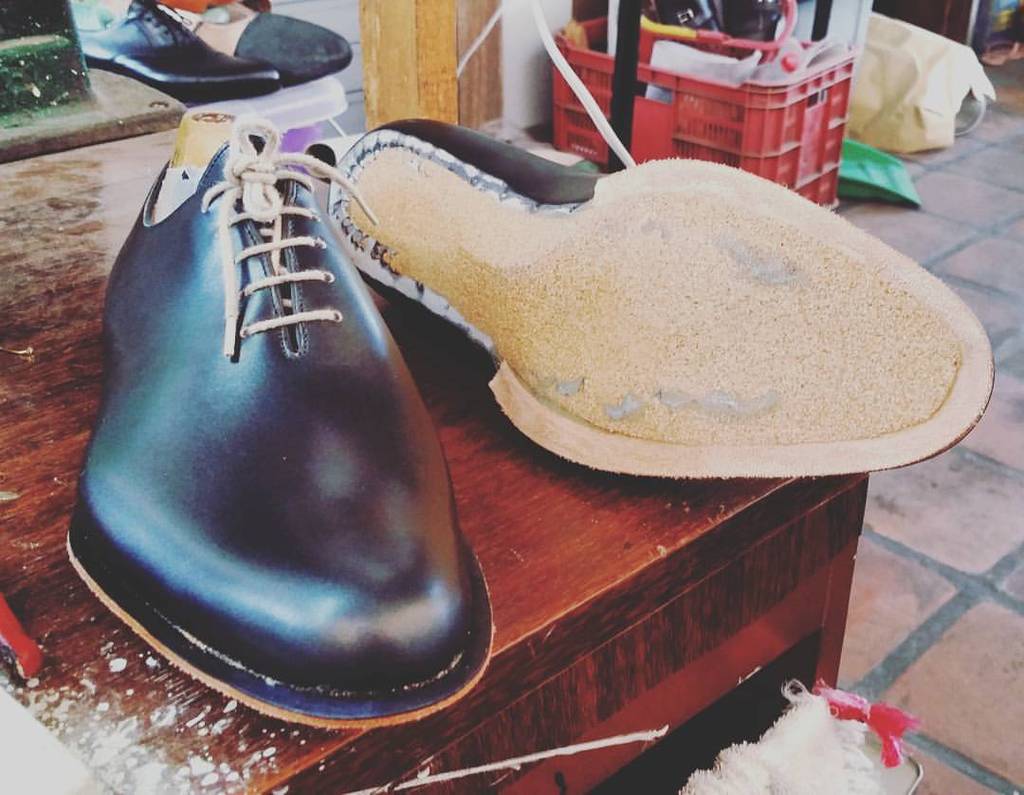

PICTURE 1

Why is he stitching a canvas strip around the welt? Also it seems that he is doing two paralel seams: one on the welt and the second one on the canvas with the same thread. I don't know if this posible as I can't figure how to 'pass' the thread from the welt to the strip.

I also noticed that the is 360 degrees welt nailed at the heel.

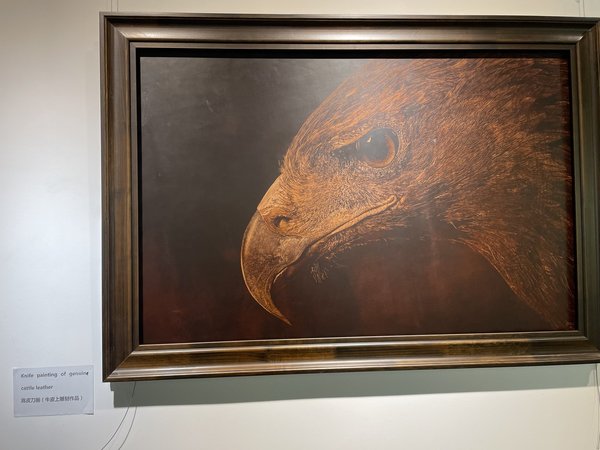

PICTURE 2

I am not sure if I understand what is going here. I can see a welt!? that is not stitched. I can see a cork board on top that probably needs to be trimmed but it seem that that the leather folds over the cork. Is just the photo angle or something is not clear here?

I think it's great that this thread welcomes genuine, direct questions regarding "shoemaking techniques and traditions" from absolutely anybody who has the inclination and ability to post them here.

I think it's great that people with years of experience actually making bespoke shoes share their knowledge, wisdom, and views for free.

so just quoting the bolded part.. 2 pictures with 2 different questions

PICTURE 1

Why is he stitching a canvas strip around the welt? Also it seems that he is doing two paralel seams: one on the welt and the second one on the canvas with the same thread. I don't know if this posible as I can't figure how to 'pass' the thread from the welt to the strip.

I also noticed that the is 360 degrees welt nailed at the heel.

PICTURE 2

I am not sure if I understand what is going here. I can see a welt!? that is not stitched. I can see a cork board on top that probably needs to be trimmed but it seem that that the leather folds over the cork. Is just the photo angle or something is not clear here?

![Lol8[1] :lol: :lol:](/styleforum_ads/smilies/lol8[1].gif)

![lol8[1].gif](http://files.styleforum.net/images/smilies/lol8[1].gif)