GasparddeColigny

Senior Member

- Joined

- Jul 23, 2010

- Messages

- 247

- Reaction score

- 214

These kinds of issues are what the 'seconds' category is created for: anyone remember the Levi's irregulars? You have to discount such an obvious defect, I can't imagine any self respecting brand letting this go out as a grade A product.

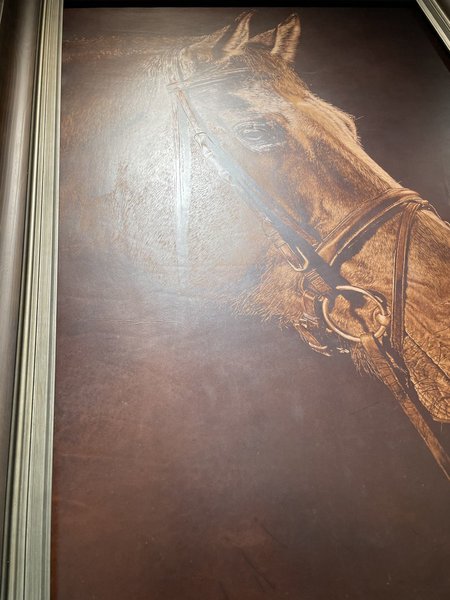

Talking about quality control, would a scuff like this be acceptable on brand new 4 figure bespoke? How would you have handled this @DWFII if a customer brought this to your attention? Would a shoe like this ever leave your workshop in the first place?

These kinds of issues are what the 'seconds' category is created for: anyone remember the Levi's irregulars? You have to discount such an obvious defect, I can't imagine any self respecting brand letting this go out as a grade A product.