- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

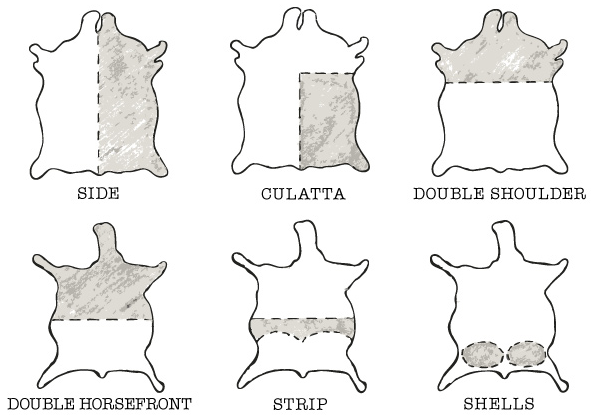

From @VegTan's post, the AE vice President of Operations in Horween video mentioned 6-7 pairs from each calfskin hide.

When I watched the Allen Edmonds Factory Tour, itself is a very good informative video compare to some other maker's video.

At 2.23, when you looking at their cutting guide on their intranet, on half a calfskin, there are 10 pairs on that! Compare that to Vegtan's scan of 10 pairs on one whole calfskin. Is that on a really large piece of calfskin hide? Can calfs get that big?

As for Cleverley and EG, when they say 3 pairs of each calfskin, are they referring to each half skin, or each whole skin?

It depends...most bespoke makers cut only one pair from one calfskin, considering that to be the limit of truly prime leather in the skin. The rest is relegated to the shoemaker and his family.

Some calf skins are larger than others--the definition for a calf may be somewhat amorphous esp. in different countries or from different tanneries--whose vested interest is to sell "calf" which commands a better price than cow.

Some of the best calf is only 8 square feet, plus or minus...more than one pair from each skin is nearly impossible.

Factories cut for maximum use...by definition they are less concerned with quality (or even alignment vis stretch) than price per square inch.