TheChihuahua

Senior Member

- Joined

- Jan 22, 2020

- Messages

- 937

- Reaction score

- 923

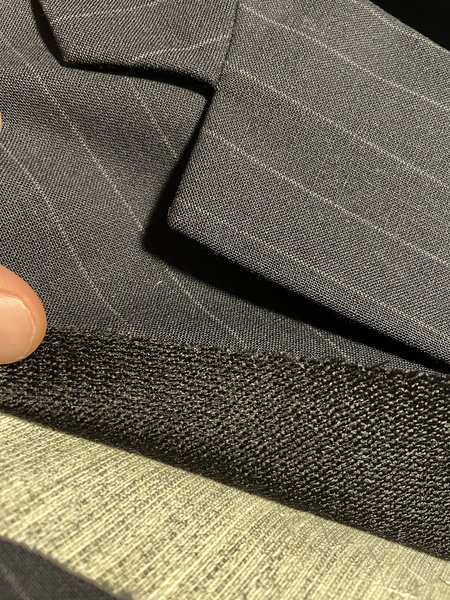

Trying to understand the technical aspect of this then. Is it fair to say that there is a canvass layer, but it is secured with an adhesive vs. sewn in?

When we see the term “floating canvass”, does that then imply that it is sewn in vs. glued?

yeah I always thought that the fused didn’t have a free standing canvas. I always thought that the canvas itself was fused to the suit’s outer material.

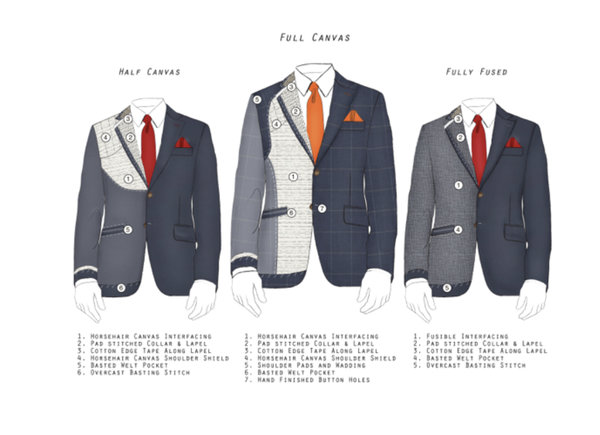

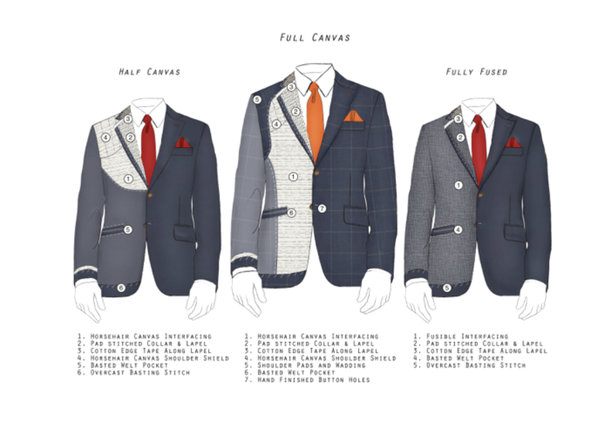

I don’t know what to make of picturea/diagrams like this that often appear when you search for information on canvassed vs fused suits.