Zapasman

Distinguished Member

- Joined

- Oct 2, 2014

- Messages

- 3,726

- Reaction score

- 2,937

Some questions with regard BR Vs. GYW shoes:

First, I wonder if in a Blake Rapid shoe construction, is there a way to hand last the upper before gluing/stiching the midsole to the insole?. If yes, how they do it?. Do they use little staples to fix the upper to the insole while hand lasting?. If so, the staples will remain there forever like in the GYW shoes.

Second, do you see any advantages in the use of a welt (GYW) when resoling your shoes?. I mean, resoling a Blake Rapid shoe is possible (with the MK machine) but I wonder if the midsole has his own disadvantages ( ex. more exposure to damage and the need to replace it) in comparison to the use of a welt. This issue is very important to me.

Third, I believe BR does not use shank, cok/paste filler and a heel rand (there is no hollow... no need to) so is a intrinsically a lighter construcction. How this affect to the structure and comfort of the shoe in comparison to a welted shoe with all those components/materials?.

Finally, do you think the use of a welt is a much better solution to keep dust and water away or both constructions offer equivalent protection to the shoe?

Thanks for your inputs.

First, I wonder if in a Blake Rapid shoe construction, is there a way to hand last the upper before gluing/stiching the midsole to the insole?. If yes, how they do it?. Do they use little staples to fix the upper to the insole while hand lasting?. If so, the staples will remain there forever like in the GYW shoes.

Second, do you see any advantages in the use of a welt (GYW) when resoling your shoes?. I mean, resoling a Blake Rapid shoe is possible (with the MK machine) but I wonder if the midsole has his own disadvantages ( ex. more exposure to damage and the need to replace it) in comparison to the use of a welt. This issue is very important to me.

Third, I believe BR does not use shank, cok/paste filler and a heel rand (there is no hollow... no need to) so is a intrinsically a lighter construcction. How this affect to the structure and comfort of the shoe in comparison to a welted shoe with all those components/materials?.

Finally, do you think the use of a welt is a much better solution to keep dust and water away or both constructions offer equivalent protection to the shoe?

Thanks for your inputs.

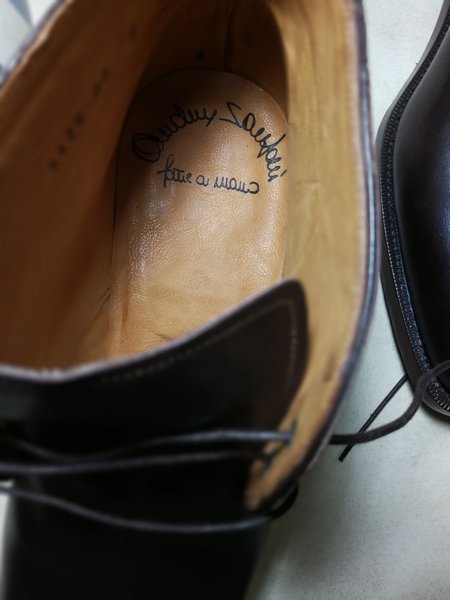

What the hell is that if not a foam forepart filler?

What the hell is that if not a foam forepart filler?