MoneyWellSpent

Distinguished Member

- Joined

- Oct 4, 2012

- Messages

- 2,697

- Reaction score

- 1,178

Good catch.

Meermin also seems to have made some design decisions purely with the cost in mind rather than aesthetics. Granted this makes them much more accessible price-wise to many more people, but they definitely don't compare to Vass.

Meermin

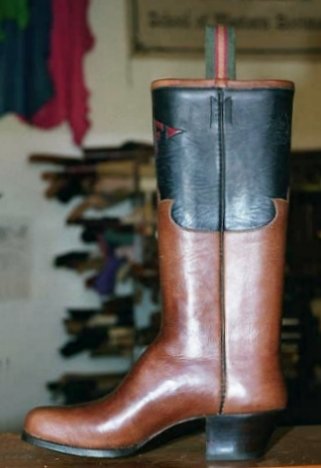

Alden

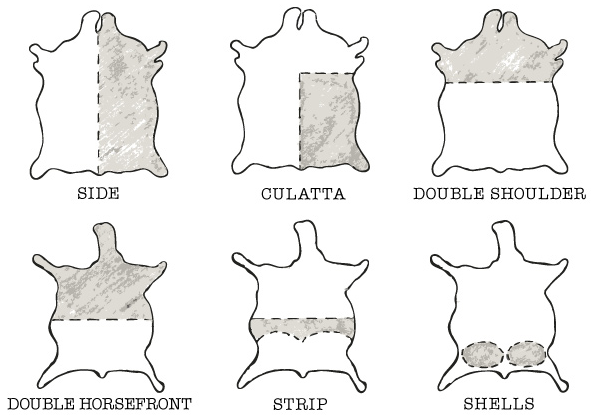

That extra seam Meermin adds really contributes no aesthetic value IMO, but it does allow them to use 3 smaller pieces of leather there vs 1 piece in the Aldens.

Good catch.