Xenon

Senior Member

- Joined

- Jan 18, 2010

- Messages

- 602

- Reaction score

- 35

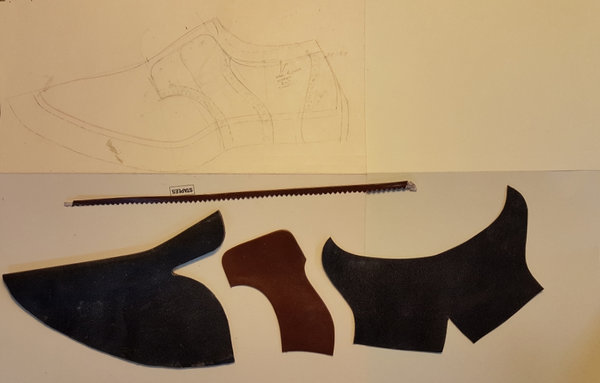

Is there such a thing. Why easier to fix? If you are referring to resoling then (as said before) having the last is not necessary if upper is properly secured to inner sole along the whole perimeter. If on the other hand any part along the perimeter of the insole the upper is not secure ( such as where the gemming canvas tore or glue joint failed) than you will need the EXACT last model and size used to make the shoe, and NOT just any standard last. The last is simply nothing less than the DNA of a shoe.

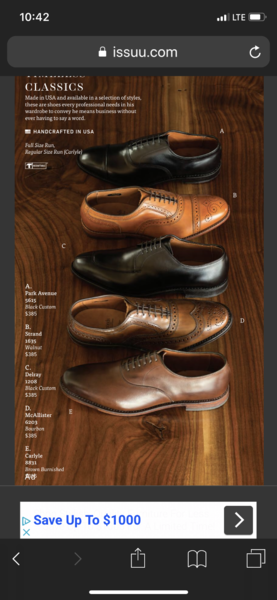

Standardized Last shape is easier to fix. A good example is DC Lewis, which outsources to Taiwan/Vietnam.

Non bespoke, last doesnt have to be first.

Is there such a thing. Why easier to fix? If you are referring to resoling then (as said before) having the last is not necessary if upper is properly secured to inner sole along the whole perimeter. If on the other hand any part along the perimeter of the insole the upper is not secure ( such as where the gemming canvas tore or glue joint failed) than you will need the EXACT last model and size used to make the shoe, and NOT just any standard last. The last is simply nothing less than the DNA of a shoe.