dbhdnhdbh

Senior Member

- Joined

- Sep 3, 2012

- Messages

- 333

- Reaction score

- 46

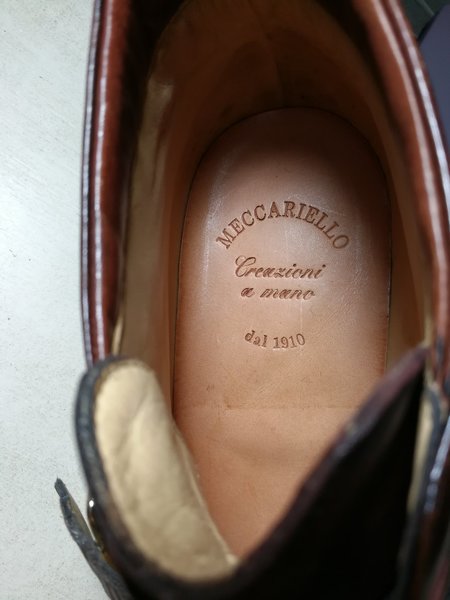

I suppose asking why devote such attention to finishing soles is like asking watchmakers and collectors why they engrave the tiny little parts buried inside the movement. "Wouldn't it keep just as good time without bothering with that?" "Probably, but that is so not the point"