traverscao

Distinguished Member

- Joined

- May 22, 2013

- Messages

- 1,437

- Reaction score

- 51

To partially interpret what is going on here:One question I still have that I can't quite find a satisfactory answer to is why the GY factories automatically replace the welt when a shoe is sent in.

The most satisfactory one I can think of (and to me it's a bit flimsy) is that the holes left in the welt from the prior sole stitching would be unpleasing to the eye. However, in shoes replaced by local cobblers where the welt is re-used, this doesn't seem to be much of an issue.

I have a hard time trying to make factory mentality, or expediency the reason as well. It is an extra step to remove the welt after the sole is cut off. It costs more to replace the welt. Replacing the welt can actually increase the risk of gemming failure, as it stresses the inseam during stitching, which would only increase the repair time/cost to the factory.

Since replacing the welt shortens the life of the upper, I find it highly annoying that they replace it whether it is needed or not.

Frankly, I find this aspect of GY-welted shoe manufacturing to be more frustrating than the questionable strength and durability of gemming. People buy GY-welted shoes under the belief that they can be resoled more than half a dozen times, but the truth is, the factories only estimate that a shoe can take 2-3 recraftings. This is purely due to the welt replacement factor.

To further complicate it, they all have a policy that if an aftermarket cobbler works on the shoes, then the factory may not perform a recraft. I understand the point behind this, being that they don't want to be working on a pair of shoes that have been completely botched by an incompetent repair man. But, this forces the customer to either choose a shorter life for their shoes by using the recrafting service, while finding security in the fact that they have the original last to assist in gemming/insole repairs as needed. Or, they can choose to lengthen the life of their shoes by sending them to a cobbler who will re-use the welt and prolong the life of the shoe. But, then they run the risk of the shoe being distorted or otherwise lost due to gemming failure issues and subsequent sizing changes, etc. It is a bit of a rock and a hard place in determining where to send shoes for repair.

I can't figure out if I'm missing a piece to the puzzle on why the factories wouldn't reuse the welt if it's in good shape, and thus multiply the number of resolings the shoe can take.

The welt used in GYW is not of high quality. Furthermore, they don't take the time and work on recrafting - they just put whatever needs to be replaced on and then hurriedly finish up the work, send the shoes back, and consider that as done. They won't take the time to examine if the welt is good or gone, or are the stitch holes on the welt is intact. Matter of fact, since all that was needed to be done was to run the shoe through a machine, why even bother to loop every thread from the sole to the welt for? That was why they'd rather replace the welt as well, disregarding the fact that it can shorten the shoes' life significantly.

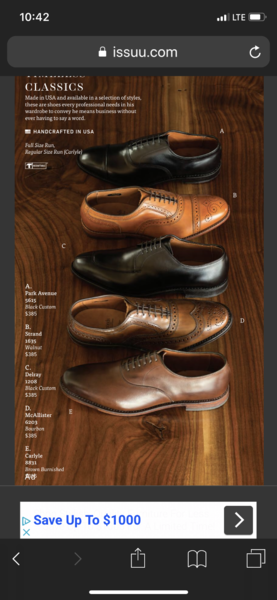

Certainly, in one way or another, yes. Much like how spray finishing and loading truck loads of ink would be the preferred method rather than slowly dying the upper and spend some more times burnishing and smoothing the edges of the sole.Maybe it would force the customer to buy a new pair of shoes?

![musicboohoo[1].gif](http://files.styleforum.net/images/smilies/musicboohoo[1].gif)