- Joined

- Oct 16, 2006

- Messages

- 38,393

- Reaction score

- 13,643

I find it ironic that your handle is a play on the word "quality".

STYLE. COMMUNITY. GREAT CLOTHING.

Bored of counting likes on social networks? At Styleforum, you’ll find rousing discussions that go beyond strings of emojis.

Click Here to join Styleforum's thousands of style enthusiasts today!

Styleforum is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

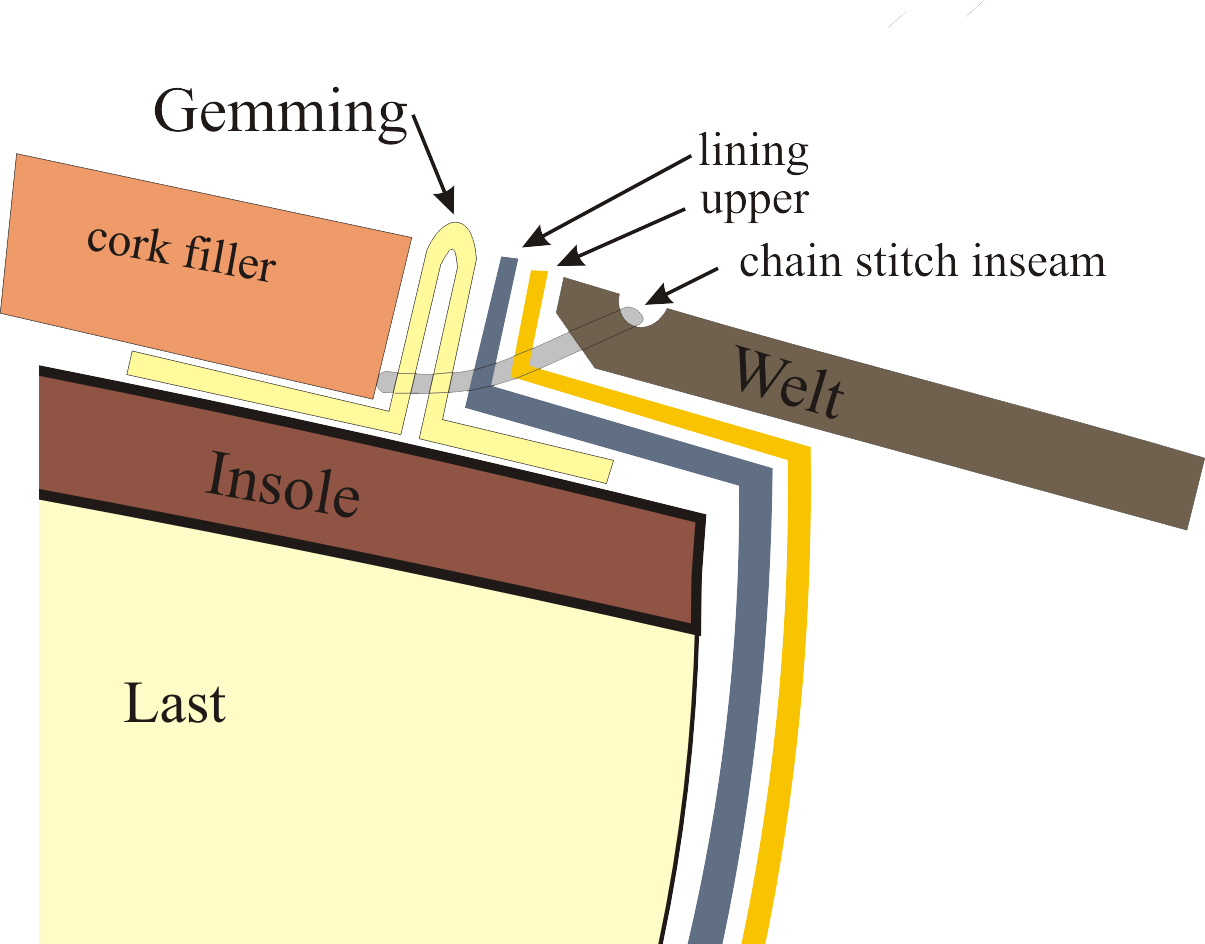

... explains the fundamental difference between Hand and Goodyear welted shoes, and Blake and Blake-rapid shoes

DW, I feel as though I might have appeared a bit strident in my response to you about colour. I apologise for this and assure you that it was not intended. Best wishes, Munky

Hand welted--the upper, the upper lining and the welt are hand sewn, with a stout thread that has been hand waxed with pine pitch and pine rosin, directly to a stout, high quality insole.

Goodyear--the upper, upper lining and the welt are machine stitched (chain stitched--kind of like on a feed sack) to a canvas strip (gemming) that has been cemented to a lower quality (sometimes not even leather) and thinner insole. Prior to the mounting of the outsole, the whole inseam is dependent on the cement (it is fundamentally a cement construction) and the durability of the canvas gemming.

Blake--the last is pulled and a Blake or McKay machine is used to sew from the inside of the shoe, through the upper and the insole, to the outsole. Sometimes this is sewn "aloft," (on the surface of the outsole); sometimes it is done to an open channel or groovel in the outsole; less often to a closed channel. Often the insole is of marginal quality or leatherboard (faux leather made like particle board) or even no real insole at all.

(The upper arrow points to the insole, the next lower to the nails, staples or stitching that secures the upper to the insole, the next lowest to the McKay/Blake stitching, next the insole filler and the lowest, the outsole.)

Blake-Rapid--the same procedures apply as with Blake except the final layer is a "midsole" ...somewhat thinner (half) than an outsole would be...and it is left proud around the margins of the shoe so that it looks like a welt. The outsole is then sewn to that margin with a machine often called a "Rapid" sole stitcher. Hence "Blake-Rapid."

--

Is it a bad idea to use dark brown Saphir cream/wax polish on these shoes? The colour is mahogany. Would medium brown be better?

http://www.nomanwalksalone.com/index.php/footwear/shoes/antique-mahogany-wilson-cap-toe-oxford.html

Question for those with experience on closed channel soles peeling: how long has it taken before this has happened?

Two pairs of C&J handgrade both started peeling at the same time after a little over a year. In terms of usage, I wear each of them 1-2 times per week and until recently I had a walking lifestyle splitting time between Manhattan and central DC. I don't tend to bother much about rain unless it's a downpour so I'm sure they've gotten wet. I've just super-glued down the peels when they've popped up so it doesn't really bother me - I'm inquiring more as a point of curiosity. Is a year or so about how long these should stay stuck down, or was C&J using cheap glue?

Question for those with experience on closed channel soles peeling: how long has it taken before this has happened?

Two pairs of C&J handgrade both started peeling at the same time after a little over a year. In terms of usage, I wear each of them 1-2 times per week and until recently I had a walking lifestyle splitting time between Manhattan and central DC. I don't tend to bother much about rain unless it's a downpour so I'm sure they've gotten wet. I've just super-glued down the peels when they've popped up so it doesn't really bother me - I'm inquiring more as a point of curiosity. Is a year or so about how long these should stay stuck down, or was C&J using cheap glue?

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.  Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.

Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.  LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.