foodguy

Distinguished Member

- Joined

- Mar 31, 2009

- Messages

- 8,691

- Reaction score

- 997

I prefer a fine grit ceramic steel for Japanese knives which makes honing easy.

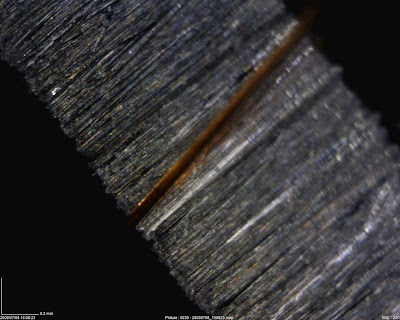

On some Japanese knives I have to use a piece of sandpaper to dull the heel of the blade to protect the middle finger when using the pinch grip. Sometimes I also sand the edges on top of the blade right in front of the handle to protect my index finger.

i use a fine grit ceramic and it is easier ... but still ... when you've got different angles on either side of the blade, getting them to agree has been a challenge for me.

I know other people who have done the sanding of the spine, too ... something called a dremel tool is apparently quite useful (if it isn't in the kitchen, i dont' know about it). I guess my knife callous has built up enough, but it's never been an issue for me.

![lol8[1].gif](https://www.styleforum.net/images/smilies/lol8[1].gif)