- Joined

- Mar 23, 2002

- Messages

- 4,625

- Reaction score

- 1,285

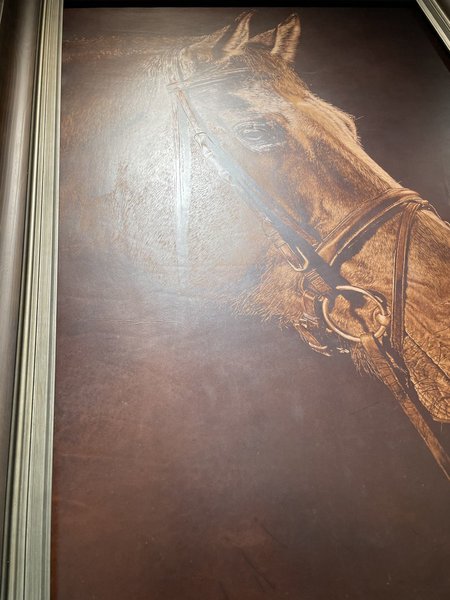

Can anyone tell me the exact name of the tool that is used to make these triangular patterns on the sole?

There are numerous wheels used in shoe making. While some have a defined purpose: fudge wheel, heel seat wheel, others are simply decorative and can have any repeating design as pattern. They are usually called 'fancy wheels'.

The pattern with the triangles is called 'scalloping' (at least in England) and can come in various configurations.