- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

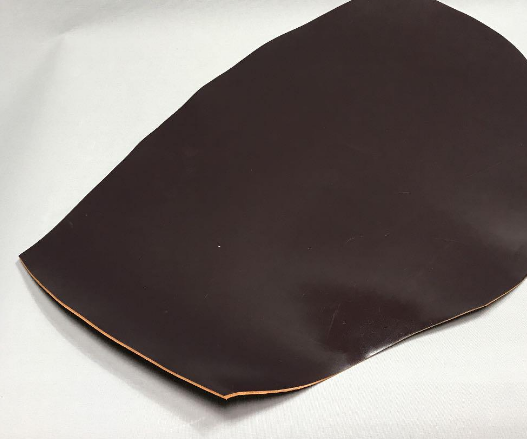

Well, I have to chuckle (no disrespect) because the second photo is one of mine.

Aside from one observation regarding the first photo, I suspect it would be more useful for me to comment on my own work rather than interpret someone else's.

In the first photo, the channel have been beveled inward from the holdfast. The leather has been cut away and removed to create that bevel. You can see that more clearly on the medial side than the lateral so maybe the insole is not finished.

As for my own work, I do not cut a bevel in the insole...ever. I cut the channel vertically into the substance of the insole and, prior to holing I moisten the leather and open and lay the sides back with a stitch prick or a bone. The bevel is created with pressure alone...no leather is removed...and because of that, it is easily re-closed when inseaming is complete.

And yes, beveling by either approach--pressure or or substance removal--makes holing easier and more accurate.

If leather is removed, it creates a "void" under the foot that must be filled or the weight of the body risks collapsing that space and weakening the insole. Some makers preserve the strip they cut out while beveling the channel and re-place it before bottoming. Some don't do anything.

I seldom it ever feel any need to fill the insole. I do it...with wool felt...only to prevent creaking when leather rubs against leather (insole against outsole).

Aside from one observation regarding the first photo, I suspect it would be more useful for me to comment on my own work rather than interpret someone else's.

In the first photo, the channel have been beveled inward from the holdfast. The leather has been cut away and removed to create that bevel. You can see that more clearly on the medial side than the lateral so maybe the insole is not finished.

As for my own work, I do not cut a bevel in the insole...ever. I cut the channel vertically into the substance of the insole and, prior to holing I moisten the leather and open and lay the sides back with a stitch prick or a bone. The bevel is created with pressure alone...no leather is removed...and because of that, it is easily re-closed when inseaming is complete.

And yes, beveling by either approach--pressure or or substance removal--makes holing easier and more accurate.

If leather is removed, it creates a "void" under the foot that must be filled or the weight of the body risks collapsing that space and weakening the insole. Some makers preserve the strip they cut out while beveling the channel and re-place it before bottoming. Some don't do anything.

I seldom it ever feel any need to fill the insole. I do it...with wool felt...only to prevent creaking when leather rubs against leather (insole against outsole).