- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

EG likely buy enough volume for JR to bend a little and provide the soles sans logo.

That would be my guess, as well.

STYLE. COMMUNITY. GREAT CLOTHING.

Bored of counting likes on social networks? At Styleforum, you’ll find rousing discussions that go beyond strings of emojis.

Click Here to join Styleforum's thousands of style enthusiasts today!

Styleforum is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

EG likely buy enough volume for JR to bend a little and provide the soles sans logo.

I find the JR logo to fade away after just one or two wearings. It's definitely not heavily imprinted on my pairs of Vass.

In fact, Vass used to remove the printed JR logo until they got feedback that customers actually prefer to see the logo on the sole.

The art of achieving a sweet, clear, clean, bottom finish is to avoid taking anything off the grain surface, if possible. That means super cleanliness and exceptional care in making. Go figure...

Then how does one get a fiddleback waist that is smooth without carving deep into the sole?

Mainly by thinning/skiving the other side (flesh side) of the outsole in the waist before it is attached to the shoe. The maker may glass the grain side of the outsole when finishing the sole, but most of the shape comes from the preparatory skiving.

^Spot on and great photo, Shoefan.

Wow, this is awesome. A lot harder work than I had imagined.

I can't imagine how much time it takes to get this all to come out all lickable n junk.

I'm betting you really hate the Jesuits then.

Rimshot worthy. Definitely. Well, not hate; I just don't like them.

^I found the discussion above to be very interesting.

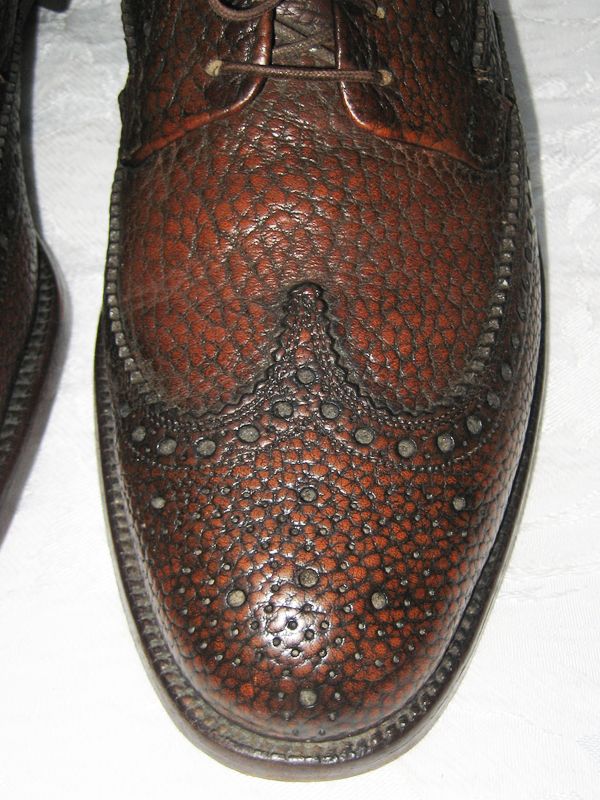

My favorite Pebble Grain Wingtips. Again, not your "every day" grain, but this'll certainly keep you regular.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.  Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.

Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.  LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.