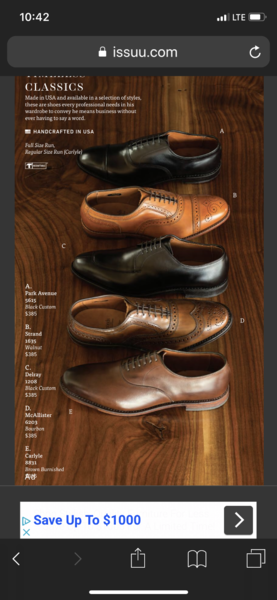

chogall

Distinguished Member

- Joined

- Aug 12, 2011

- Messages

- 6,562

- Reaction score

- 1,166

Norm

Normal.

X-post from the Meermin thread:

Isn't the insole of a handwelted shoe supposed to be flat? This pair of LM shoes has some kind of stitching groove on the insole, almost looks like they are Blake stitched.

Is this normal?

Normal.

![Crackup[1] :crackup: :crackup:](/styleforum_ads/smilies/crackup[1].gif)