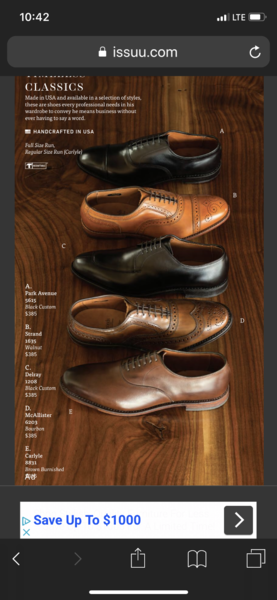

I don't even consider glue construction worthy to be mentioned. We are talking about low-high end market. Both considered made in the USA mid level quality Allen Edmonds and Alden uses Goodyear construction.

When I lived in New York only Saks fifth avenue sold Santoni and Magnanni. Allen Edmonds was available almost on every block.

When I lived in New York only Saks fifth avenue sold Santoni and Magnanni. Allen Edmonds was available almost on every block.

Last edited: