Circlingdrains

New Member

- Joined

- Jul 31, 2022

- Messages

- 2

- Reaction score

- 5

Hello, I am a long time lurker who's recently had to buy a new work wardrobe due to COVID weight gain. Shirt shrinkage and the hassle that accompanies having to estimate shirt shrinkage following a few washes have been a long standing frustration of mine. It makes trying new makes of shirts difficult since you now not only have to account for differences in fit, but also differences in shrinkage.

Searching through Styleforum's archives indicates this is a frustration shared by many. I therefore thought it would make sense to have a repository of knowledge focussed on shirt shrinkage.

I recently bought several Harvie & Hudson shirts and saw an opportunity to kick start something like this.

Methodology

2 shirts of size 15.5 inches, sleeve length 35.5 were bought online. A series of measurements were taken before the shirts were laundered at 50C. The shirts were washed, then measured until they stopped shrinking.

The shirts tested were as follows:

Shirt 1: Harvie & Hudson Blue fine Twill, size 15.5L, sleeve 36, shortened to 35.5.

Shirt 2: Harvie & Hudson Blue Graph Poplin, size 15.5L, sleeve 36, shortened to 35.5.

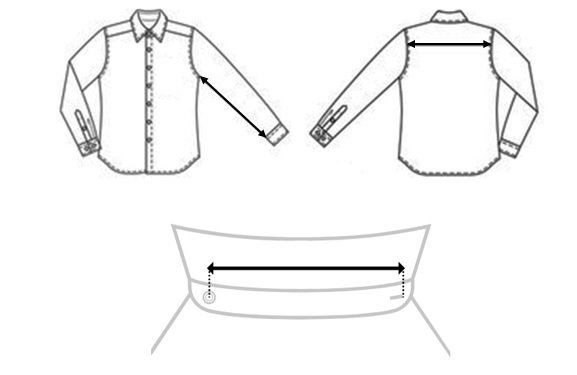

Measurements were taken the back, on the collar, and along the lower seam of the right sleeve.

Results

Shirt 1: Blue fine Twill, size 15.5L, sleeve 36, shortened to 35.5:

Shirt 2: Blue Graph Poplin, size 15.5L, sleeve 36, shortened to 35.5:

-----

Looking at the results, it seems to me I should be laundering H&H shirts at least 3 times before wearing them, and sizing down half a collar size when buying twill shirts.

I will continue to update this thread when I buy new shirts but hopefully, others can contribute.

Searching through Styleforum's archives indicates this is a frustration shared by many. I therefore thought it would make sense to have a repository of knowledge focussed on shirt shrinkage.

I recently bought several Harvie & Hudson shirts and saw an opportunity to kick start something like this.

Methodology

2 shirts of size 15.5 inches, sleeve length 35.5 were bought online. A series of measurements were taken before the shirts were laundered at 50C. The shirts were washed, then measured until they stopped shrinking.

The shirts tested were as follows:

Shirt 1: Harvie & Hudson Blue fine Twill, size 15.5L, sleeve 36, shortened to 35.5.

Shirt 2: Harvie & Hudson Blue Graph Poplin, size 15.5L, sleeve 36, shortened to 35.5.

Measurements were taken the back, on the collar, and along the lower seam of the right sleeve.

Results

Shirt 1: Blue fine Twill, size 15.5L, sleeve 36, shortened to 35.5:

| Pre-Wash | Wash 1 | Wash 2 | Wash 3 | Wash 4 | |

| Collar | 16.375 | 16.25 | 16.125 | 16.125 | 16.125 |

| Back | 18.625 | 18.375 | 18.25 | 18.25 | 18.25 |

| Sleeve | 19.75 | 19.25 | 19.125 | 19.125 | 19.125 |

Shirt 2: Blue Graph Poplin, size 15.5L, sleeve 36, shortened to 35.5:

| Pre-Wash | Wash 1 | Wash 2 | Wash 3 | Wash 4 | |

| Collar | 16.125 | 15.875 | 15.75 | 15.625 | 15.625 |

| Back | 19 | 18.625 | 18.625 | 18.625 | 18.625 |

| Sleeve | 19.75 | 19.375 | 19.375 | 19.375 | 19.375 |

-----

Looking at the results, it seems to me I should be laundering H&H shirts at least 3 times before wearing them, and sizing down half a collar size when buying twill shirts.

I will continue to update this thread when I buy new shirts but hopefully, others can contribute.

Attachments

Last edited: