- Joined

- Jun 1, 2011

- Messages

- 8,762

- Reaction score

- 5,597

Crockett & Jones was founded on the eve of a revolution. When the company opened its first factory in 1879, it operated much like the tailoring houses on Savile Row – the factory cut the leather parts, which were then sent to outworkers to be sewn together and brought back for welting and finishing. A true cottage industry.

Across the Atlantic Ocean, the revolution had already started. Given the technological limitations of the time, it was not televised. In 1869, Charles Goodyear Jr. (son of the rubber vulcanizer of tire fame) patented a machine that could welt a shoe in a matter of minutes, a process which would take a hand welter hours. Over the strikes and protestations of Luddite shoe industry operatives, this invention eventually transformed the shoemaking industry in Northampton.

Instead of sending leather out to be sewn by hand, operatives in the new regime had to come to the factory to use the machines. Crockett & Jones moved to a new, larger factory, in Perry Street in 1890. Crockett & Jones remains in this same factory today, albeit with a major addition in 1911. The factory is surrounded by houses, which would likely have been filled with factory workers generations ago, before cars were in common use.

To the modern ear, “factory” implies some sort of automated process in which raw materials are set adrift on a conveyer built, and, after a few minutes in some rumbling aluminum tank, appear as shoes. The Crockett & Jones factory bears no resemblance to this image. The factory today uses essentially the same process as it did when it first opened. Leather uppers are cut, then closed, then lasted, then welted to the insole, then attached with both glue and stitching to the outsole, and then finished with heels and some polish.

While most steps involve some kind of machine, the factory operatives would likely be surprised and offended if you told them they weren't working with their hands. Consider, for instance, the trimming of the soles, a Crockett & Jones specialty. The soles are cut far bigger than the last; there is a castor knife used to encompass all last shapes throughout the size range. After the soles are stitched to the welt, they are trimmed down to their final shape. This is done in stages. The first trim is a rough cut that also cuts a groove for the sole stitch (Rough Rounding), with the finest work left to the final trimmer (Edge Trimmer) . The heels follow a similar process. They are trimmed roughly and then go through stages of rough to fine emery paper. The operatives shape the soles and heels by eye. Trim too much and you risk slicing into the welt stitching or the sole channel. Don't trim enough and you leave the shoe looking clunky and inelegant. Crockett and Jones trusts their craftsman to trim the soles very tightly, which is part of what gives their shoes a sleeker look than most Goodyear welted shoes. This isn't a setting that they've punched into a machine – it's a skill and a focus that their operatives have acquired, based on a priority that the company has given them.

All of Crockett & Jones ready-to-wear shoes are divided into two parts – Mainline and Handgrade. Both go through the same manufacturing process. At a given station – a closer, say – you will see both Mainline and Handgrade shoes. The only significant differences in the production of the two is that Handgrade shoes all have channeled soles - meaning you can't see any stitching on the sole – and Handgrade shoes require more antiquing and burnishing since they use leather that comes to the factory less finished. The more important differences are that Handgrade shoes use better quality leather and different, often newer, lasts. For instance, the sleeker round-toe 363 last, less than five years old, is only used on Handgrade shoes. The 369 last – currently only available in the Paris store – is a new chisel-toe last, also only used in Handgrade shoes. The Mainline shoes use classic C&J lasts such as the hugely popular 348.

These subtle innovations in shoe silhouette are oscillations around the core of what Crockett & Jones shoes represent – well-made, beautiful English shoes that will look even better 15 years and a few resoles later.

The Crockett & Jones factory showroom.

The showroom, Part II.

A boot from the early 20s. Note the fine stitching.

A vintage ladies shoe. In the 20s-40s, Crockett and Jones sold more women's shoes than men's.

Beautiful scalloping and stitching.

Crockett and Jones makes some of the finest country boots you'll ever see. This is the Skye. The Islay in scotch grain will be on my shopping list for my next trip to NYC.

Horween cordovan.

The leather will end up the same color as that shoe.

Lining canvas, and upper sewn together.

Hand-sewing the toe, using some piano wire as needle.

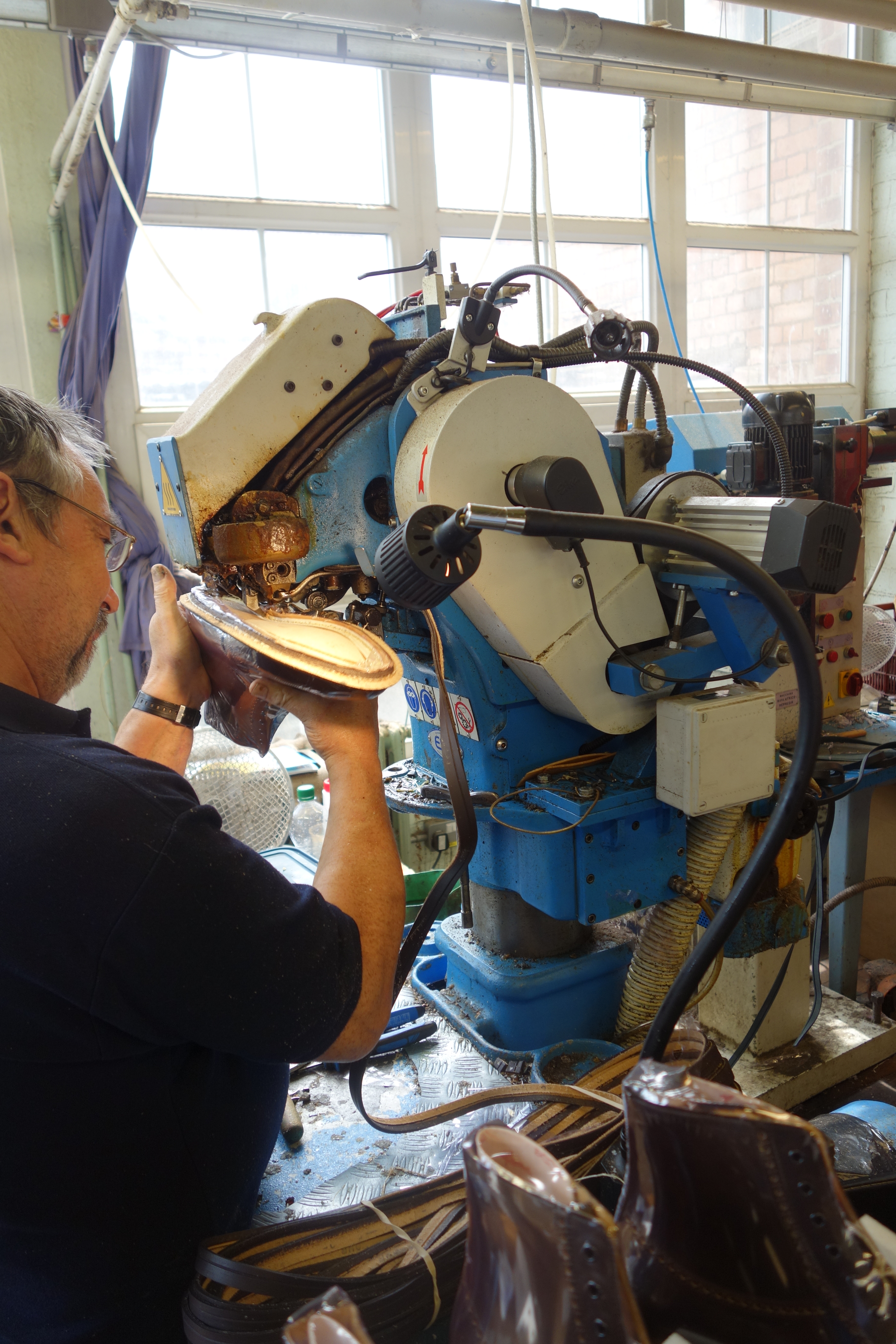

The Goodyear welting machine.

The ribbing, upper, and welt sewn together.

Welts ready for use.

Monks waiting to be antiqued.

It's July, but in England everyone still wears a coat to work.

The best-selling 348 last.

Across the Atlantic Ocean, the revolution had already started. Given the technological limitations of the time, it was not televised. In 1869, Charles Goodyear Jr. (son of the rubber vulcanizer of tire fame) patented a machine that could welt a shoe in a matter of minutes, a process which would take a hand welter hours. Over the strikes and protestations of Luddite shoe industry operatives, this invention eventually transformed the shoemaking industry in Northampton.

Instead of sending leather out to be sewn by hand, operatives in the new regime had to come to the factory to use the machines. Crockett & Jones moved to a new, larger factory, in Perry Street in 1890. Crockett & Jones remains in this same factory today, albeit with a major addition in 1911. The factory is surrounded by houses, which would likely have been filled with factory workers generations ago, before cars were in common use.

To the modern ear, “factory” implies some sort of automated process in which raw materials are set adrift on a conveyer built, and, after a few minutes in some rumbling aluminum tank, appear as shoes. The Crockett & Jones factory bears no resemblance to this image. The factory today uses essentially the same process as it did when it first opened. Leather uppers are cut, then closed, then lasted, then welted to the insole, then attached with both glue and stitching to the outsole, and then finished with heels and some polish.

While most steps involve some kind of machine, the factory operatives would likely be surprised and offended if you told them they weren't working with their hands. Consider, for instance, the trimming of the soles, a Crockett & Jones specialty. The soles are cut far bigger than the last; there is a castor knife used to encompass all last shapes throughout the size range. After the soles are stitched to the welt, they are trimmed down to their final shape. This is done in stages. The first trim is a rough cut that also cuts a groove for the sole stitch (Rough Rounding), with the finest work left to the final trimmer (Edge Trimmer) . The heels follow a similar process. They are trimmed roughly and then go through stages of rough to fine emery paper. The operatives shape the soles and heels by eye. Trim too much and you risk slicing into the welt stitching or the sole channel. Don't trim enough and you leave the shoe looking clunky and inelegant. Crockett and Jones trusts their craftsman to trim the soles very tightly, which is part of what gives their shoes a sleeker look than most Goodyear welted shoes. This isn't a setting that they've punched into a machine – it's a skill and a focus that their operatives have acquired, based on a priority that the company has given them.

All of Crockett & Jones ready-to-wear shoes are divided into two parts – Mainline and Handgrade. Both go through the same manufacturing process. At a given station – a closer, say – you will see both Mainline and Handgrade shoes. The only significant differences in the production of the two is that Handgrade shoes all have channeled soles - meaning you can't see any stitching on the sole – and Handgrade shoes require more antiquing and burnishing since they use leather that comes to the factory less finished. The more important differences are that Handgrade shoes use better quality leather and different, often newer, lasts. For instance, the sleeker round-toe 363 last, less than five years old, is only used on Handgrade shoes. The 369 last – currently only available in the Paris store – is a new chisel-toe last, also only used in Handgrade shoes. The Mainline shoes use classic C&J lasts such as the hugely popular 348.

These subtle innovations in shoe silhouette are oscillations around the core of what Crockett & Jones shoes represent – well-made, beautiful English shoes that will look even better 15 years and a few resoles later.

The Crockett & Jones factory showroom.

The showroom, Part II.

A boot from the early 20s. Note the fine stitching.

A vintage ladies shoe. In the 20s-40s, Crockett and Jones sold more women's shoes than men's.

Beautiful scalloping and stitching.

Crockett and Jones makes some of the finest country boots you'll ever see. This is the Skye. The Islay in scotch grain will be on my shopping list for my next trip to NYC.

Horween cordovan.

The leather will end up the same color as that shoe.

Lining canvas, and upper sewn together.

Hand-sewing the toe, using some piano wire as needle.

The Goodyear welting machine.

The ribbing, upper, and welt sewn together.

Welts ready for use.

Monks waiting to be antiqued.

It's July, but in England everyone still wears a coat to work.

The best-selling 348 last.

Last edited: