- Joined

- Oct 16, 2006

- Messages

- 38,393

- Reaction score

- 13,643

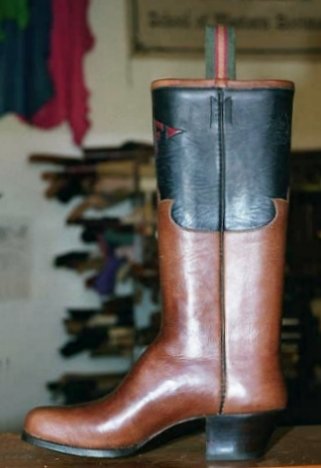

Too bad you didn't deconstruct those shells...would have been interesting. Oh! but those were hand welted, weren't they?

These shells were hand-welted. I haven't worn Goodyear shoes in some time now.

One has to wonder what the mold was growing on? All living things need nourishment to survive...can't imagine varnish providing much if any.

It was growing on the moisture from my sweaty ass feet.