- Joined

- Mar 23, 2002

- Messages

- 4,624

- Reaction score

- 1,282

Here is an article giving more details:

http://news.bbc.co.uk/1/hi/england/london/3007675.stm

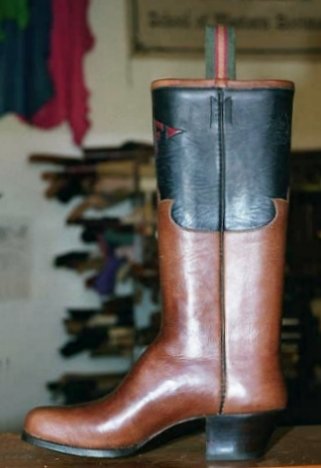

The construction of the boot is something like double Norwegian; triple soled; hob-nailed.

Those are the boots used to climb Everest?

Here is an article giving more details:

http://news.bbc.co.uk/1/hi/england/london/3007675.stm

The construction of the boot is something like double Norwegian; triple soled; hob-nailed.

![Nod[1] :nodding: :nodding:](/styleforum_ads/smilies/nod[1].gif)