OtterMeanGreen

Distinguished Member

- Joined

- Feb 4, 2017

- Messages

- 5,162

- Reaction score

- 3,090

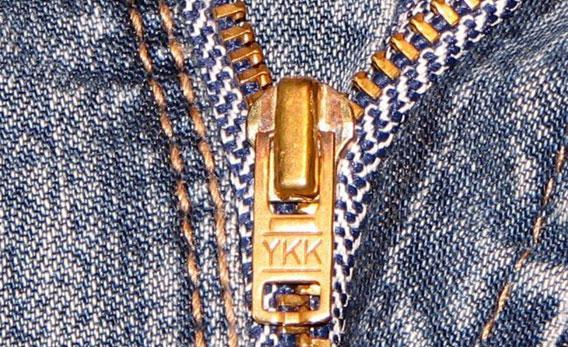

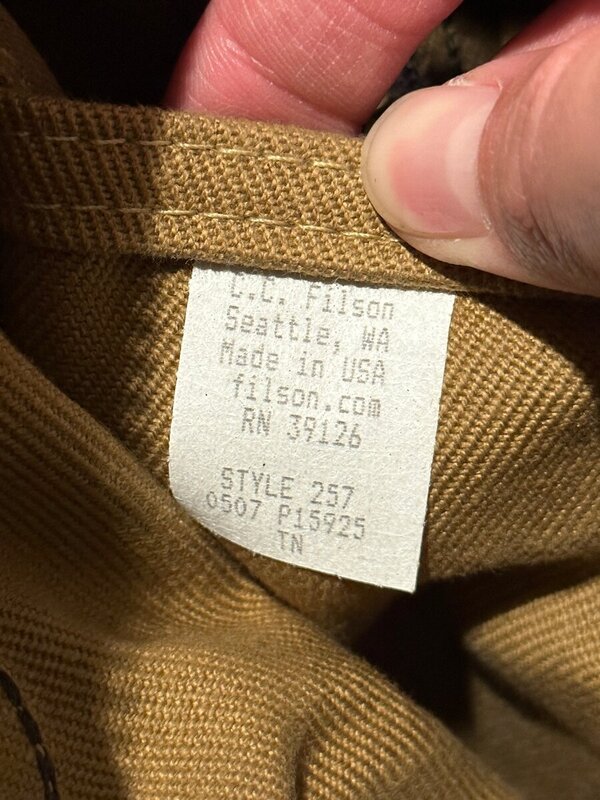

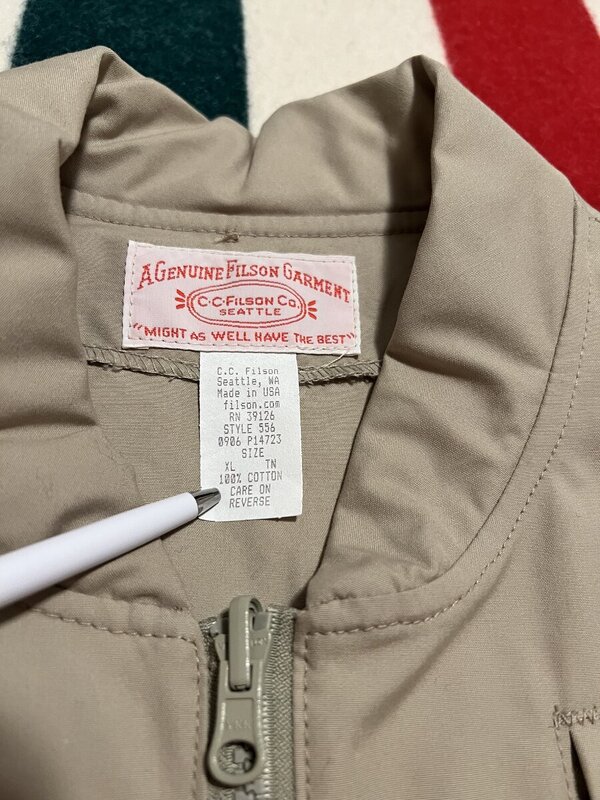

lol, that's an industrial sewing machine! notice the cut length of zippers lying to the right. its sewing the zipper to the leather. Zipper is manufactured in a long continuous strand. it is then cut to length, and keepers are attached at the ends. this determines the final length. it is sold in standard lengths to manufacturers. Filson uses a lot of it, they use 'custom' lengths. the rolls are provided and they cut them to length to use as they need fit. I have no idea what kind of machine YKK sent them to use. I do know that manufacturing a zipper is very complicated, you have to make the individual teeth which is an industrial process (go back to the thread, pretty involved) then they have to be attached to the tape, and the keepers and stops (also individually manufactured) are attached. its highly unIikely, but possible that YKK supplies Filson with a machine where all the teeth are fed into it and it assembles them onto the tape, what do I know? either way that is assembling, not manufacturing. I am only going by what ive read and what ive been told. personally, I'm satisfied with that, but feel free to dig deeper and get the whole story.

That’s one snapshot of an entire process, the blurb under the picture is why I shared it. Why would YKK admit to not being able to keep up with Filson’s demands? why who they supply them with a very rare machine to a customer? Doesn’t make any sense if it’s just for cutting and sewing, something you don’t need a special secret machine for? If anything further digging is required, as I don’t feel that the argument is ironclad. The article I provided was written 1 year and 8 months after yours and actually states the YKK zipper machine, even going as far as openly saying they’re making their own zippers. Plus there’s more to a zipper that just the teeth, the pull & slider themselves are part of the manufacturing process, this machine could very well be making the both pull & sliders from scratch as article is eluding to.

Last edited: