suitforcourt

Distinguished Member

- Joined

- Jan 11, 2012

- Messages

- 8,242

- Reaction score

- 19,659

This is the official thread for submissions to the 2019 shoe revival challenge.

Rules:

1. This thread shall remain open until September 6, 2019, 12am EST. Any entries submitted after this time, will not be considered;

2. Every entry must submit at least 6 before, and at least 6 after pictures. More is fine. Less is not;

3. Every participant can submit 1 pair of shoes for consideration.

Good luck to all. And have fun!!!

-------------------------

The rules once again:

Rules of the challenge:

Rules:

1. This thread shall remain open until September 6, 2019, 12am EST. Any entries submitted after this time, will not be considered;

2. Every entry must submit at least 6 before, and at least 6 after pictures. More is fine. Less is not;

3. Every participant can submit 1 pair of shoes for consideration.

Good luck to all. And have fun!!!

-------------------------

The rules once again:

Rules of the challenge:

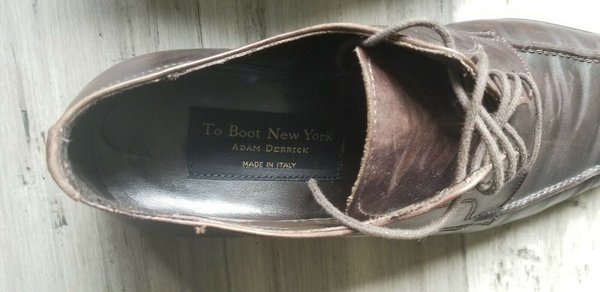

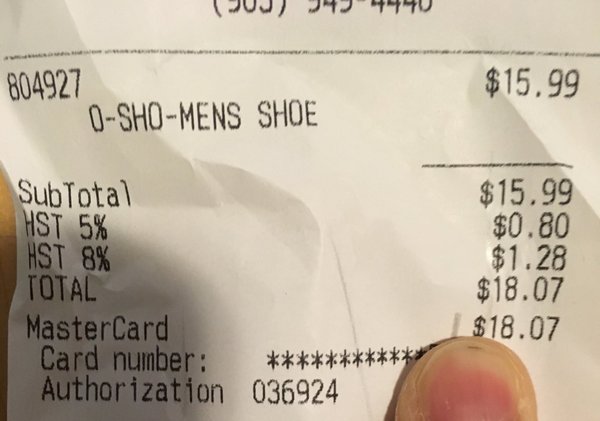

- Purchase shoes for $17.50 USD or less (taxes, shipping, and other online or credit card fees are excluded). Must have receipt (must be used but does not have to be vintage). The receipt must show the following: date of purchase, and price;

- Receipt must show date and time AFTER August 6, 2019 10:30am EST;

- All work must be done by yourself;

- Before and after photos must be taken - minimum 6 before and 6 after. More is fine. Less is not;

- Full explanation of steps taken, and work done. Points are allotted on that basis;

- Participants may enter more than one pair of shoes, BUT only one pair will be used for the competition. Make it clear which pair you are using for same;

- Contest ends September 6 at 12am EST. This longer time line is to encourage international participants who may have extended shipping times to receive shoes.