Quarantanove

Member

- Joined

- Feb 8, 2012

- Messages

- 14

- Reaction score

- 0

I know that hand welting is more durable than goodyear machine welting, but what are the aesthetic differences between the two?

Thank you!

Thank you!

STYLE. COMMUNITY. GREAT CLOTHING.

Bored of counting likes on social networks? At Styleforum, you’ll find rousing discussions that go beyond strings of emojis.

Click Here to join Styleforum's thousands of style enthusiasts today!

Styleforum is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

I know that hand welting is more durable than goodyear machine welting, but what are the aesthetic differences between the two?

Thank you!

There are no aesthetic differences.

The welting ('inseam') is hidden inside the finished shoe. It is on the underside of the insole and covered by the outsole.

You can distinguish visibly (or with your fingertips) between the two as the hand welting leaves a row of dimples on the top of the insole.

Bottom: fully prepared insole with ‘feather’ (ditch) and ‘holdall’ (dam) and all pre-poked awl holes in place.

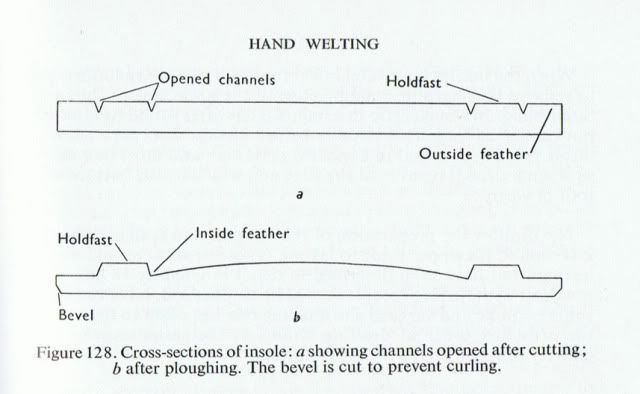

Here is an illustration that appears in R.A. Salaman's Dictionary of Leather-Working Tools c.1700-1950, George Allen & Unwin, London--perhaps the definitive work of its kind...and eminently British.

The terminology used is correct... feather, holdfast, and channel. (although the illustrator calls the channel a "channel and feather," it will be noted that this is corrected in the accompanying descriptions).

While admittedly not important in the larger scheme of things, there is a proper and traditional lexicon...recognized by English-speaking shoemakers worldwide...that is, if nothing else, useful for conveying accurate information.

This outside line is called the outside feather. A further mark is now made 3/16 in. in from the first one and carried all the way round the insole. This is called the inside feather and the space between the two lines is known as the holdfast. A sharp pointed knife is then held between the thumb and fingers.......The bottom of the insole is then wetted and the cuts are opened out into channels as shown in figure 128a.

A steel feather 'plough' is now used to cut away the inside and outside feathers by a pushing action and leaves the insole as shown in figure 128b. Approximately one-third of the substance is taken away in this operation leaving the holdfast standing above the general level as shown.

J.H. Thornton - Textbook of footwear manufacture - Third edition 1964, page 290/291

J.H. Thornton - eminently British - talks about an outside and an inside feather. For him the channel is a preparatory step to reach the result, which are two feathers forming a holdfast..

"A rose by any other name would smell as sweet"

Thornton was writing in the 1950's and primarily from the perspective of mass manufacturing...although he did touch upon some, few, handwelting techniques..

Therefore, if 'inside feather' was good enough for him than it is good enough for me.

[COLOR=FF00AA]I know that hand welting is more durable than goodyear machine welting[/COLOR], but what are the aesthetic differences between the two?

Thank you!

I know that hand welting is more durable than goodyear machine welting, but what are the aesthetic differences between the two?

Thank you!

Why do you believe this to be true?

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.  Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.

Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.  LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.