Torchiere

Active Member

- Joined

- Apr 30, 2009

- Messages

- 33

- Reaction score

- 18

Mind sharing where you're seeing the AW14 collection for IS?

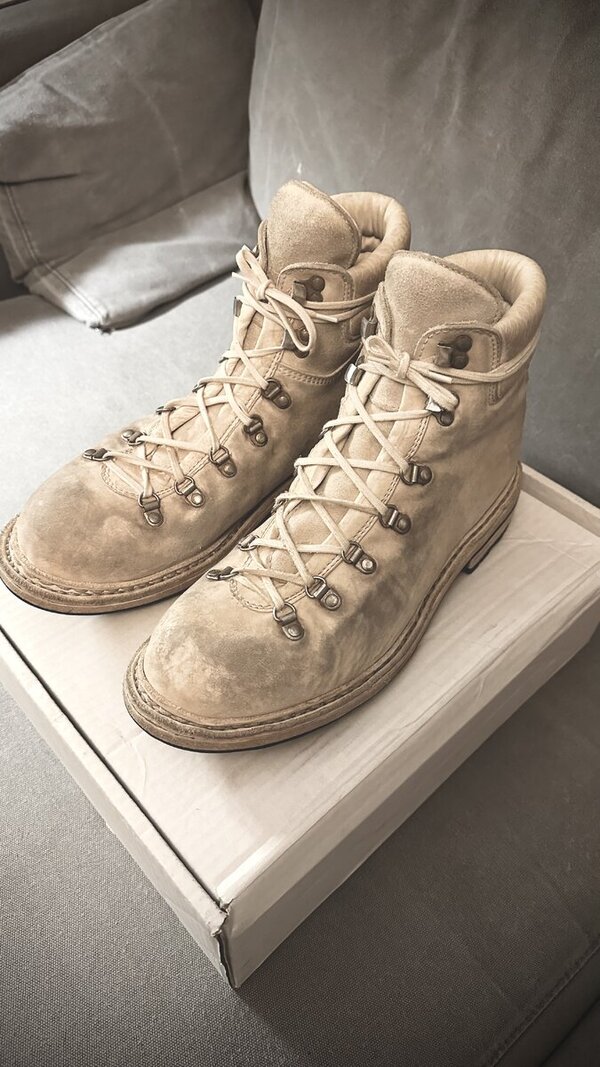

Got that cowhide messenger bag to replace the canvas one I lost and a pair of dirty white roo derbies coming in from IS.

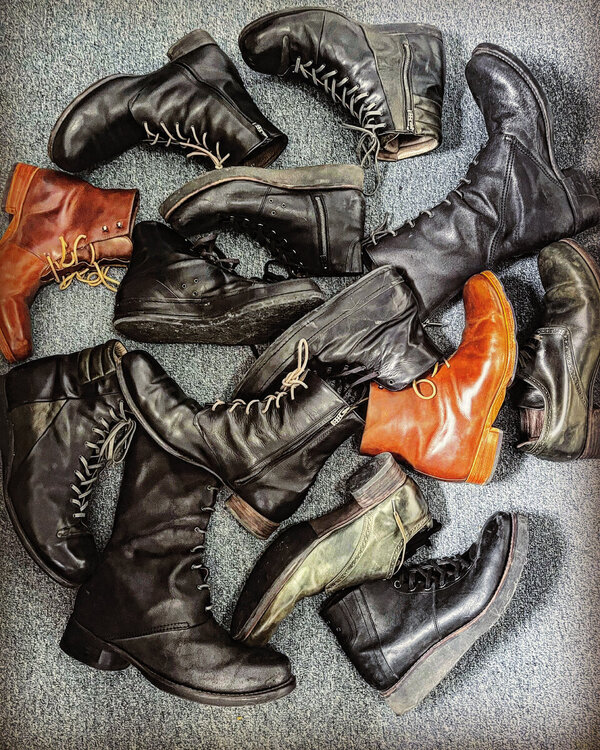

For A/W '14 I ordered up another pair of derbies in wolf fish and boots in needle punched python. I'd considered the Devoa ankle boots, but ended up passing.

Mind sharing where you're seeing the AW14 collection for IS?